Most Popular Resources

In The Packshed

Planning an Efficient and Safe Wash/Pack Area

A Guide to Cleaning, Sanitizing, and Disinfecting for Produce Farms

Cooler Construction Options – Walls and Panels

Drains for Produce Farms

Spring Cleaning – Farm Cooler Checklist

Finish Surfaces for Produce and Food Areas

Floor Design for Vegetable Wash, Pack and Storage Areas

Improving Handwashing Stations

Hygienic and Sanitary Design for Produce Farms

Postharvest Equipment

Bins, Buckets, Baskets & Totes

CoolBots(TM): Inexpensive Cold Storage

Doser for Small Scale Vegetable Washing with Sanitizer

Spring Cleaning – Farm Cooler Checklist

Greens Spinners for Farm Use

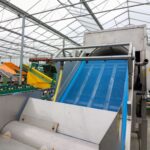

Greens Washline from China

Hanging Hoses

Innovation in Small Scale Vegetable Washing Equipment

Spray Tables for Produce Farms

Thermostats for Agriculture

Vegetable Wash Sinks, Tanks, Tubs and Basins: Upgrades for Efficiency and Ergonomics

Postharvest Case Studies

The BarnHouse: Optimized for Modern Day Vegetable Farming at Footprint Farm

Last Resort Farm Not Stalled by Dairy Barn Conversion

Wheels Keep Things Rolling at Root 5 Farm

Giving a Dairy Barn New Life at New Leaf Organics

Mighty Clean and Comfortable – A New Wash and Pack Shed at Mighty Food Farm

Simple Ergonomics and Lean Thinking at Chewonki Farm

Events (Workshops, Webinar’s & Presentations)

Posts (Most Recent)

- Shipping Container Delivers the Goods for Ascutney Harvest

Lauren Mucha and Oliver Owen own and operate Ascutney Harvest in Ascutney, Vermont. Their half-acre market garden consists mostly of mixed vegetables and herbs which require washing and packing before heading off to two different farmers markets and a few wholesale vendors. They are fairly new to this land, and needed to make a quick …

Lauren Mucha and Oliver Owen own and operate Ascutney Harvest in Ascutney, Vermont. Their half-acre market garden consists mostly of mixed vegetables and herbs which require washing and packing before heading off to two different farmers markets and a few wholesale vendors. They are fairly new to this land, and needed to make a quick …Continue reading “Shipping Container Delivers the Goods for Ascutney Harvest”

- Planning Tames the Postharvest Beast at Wild Work Farm

Lissa Goldstein runs the farming operation at Wild Work Farm in Keene Valley, New York nestled in the Adirondack Mountains. Wild Work is a diversified vegetable farm with some blueberries and fruit trees. When Lissa heard we were building out examples of wash/pack areas she reached out to share details of her shipping container project, …

Lissa Goldstein runs the farming operation at Wild Work Farm in Keene Valley, New York nestled in the Adirondack Mountains. Wild Work is a diversified vegetable farm with some blueberries and fruit trees. When Lissa heard we were building out examples of wash/pack areas she reached out to share details of her shipping container project, …Continue reading “Planning Tames the Postharvest Beast at Wild Work Farm”

- Reinventing the Wheel: Easing Movement and Adding Flexibility

Could wheels help you out in your pack shed? When do they make sense and when don’t they? Below are examples illustrating how growers are using wheels in different ways to ease the movement of product out of the field and around the wash/pack. Why Scale, Diversity, Markets and Bins Matter? At the heart of …

Could wheels help you out in your pack shed? When do they make sense and when don’t they? Below are examples illustrating how growers are using wheels in different ways to ease the movement of product out of the field and around the wash/pack. Why Scale, Diversity, Markets and Bins Matter? At the heart of …Continue reading “Reinventing the Wheel: Easing Movement and Adding Flexibility”

- Farmer’s Favorites: The AZS Rinse Conveyor

Vegetable growers are seeking tools to improve flexibility and efficiency in the packshed. The AZS Rinse Conveyor is becoming a popular piece of equipment to meet the need to rinse off a variety of crops. Table of Contents OverviewCommon Uses Cost User Reviews Use as a Bin Washer Contact information This machine is designed and …

Vegetable growers are seeking tools to improve flexibility and efficiency in the packshed. The AZS Rinse Conveyor is becoming a popular piece of equipment to meet the need to rinse off a variety of crops. Table of Contents OverviewCommon Uses Cost User Reviews Use as a Bin Washer Contact information This machine is designed and …Continue reading “Farmer’s Favorites: The AZS Rinse Conveyor”

- Farmer’s Favorite: Univerco Barrel Washer

Josh Carter is the manager of the market garden at Shelburne Farms. They grow three acres of certified organic fruit, vegetables and flowers while supporting an educational mission. They wanted to eliminate a bottleneck in their postharvest systems of hand washing roots with hoses and power washers, turning them around by hand or in crates. …

Josh Carter is the manager of the market garden at Shelburne Farms. They grow three acres of certified organic fruit, vegetables and flowers while supporting an educational mission. They wanted to eliminate a bottleneck in their postharvest systems of hand washing roots with hoses and power washers, turning them around by hand or in crates. …Continue reading “Farmer’s Favorite: Univerco Barrel Washer”

- Farmer’s Favorites: Shipping Containers and Their Use on Vegetable Farms

Farming requires lots of space. Space to grow vegetables, conditioned space to store harvested produce, and a secure space to house tools out of the weather. Barns and tool sheds can be expensive, and building takes time. If you’re farming on rented land, it’s even harder to justify the investment in a permanent building. Shipping …

Farming requires lots of space. Space to grow vegetables, conditioned space to store harvested produce, and a secure space to house tools out of the weather. Barns and tool sheds can be expensive, and building takes time. If you’re farming on rented land, it’s even harder to justify the investment in a permanent building. Shipping …Continue reading “Farmer’s Favorites: Shipping Containers and Their Use on Vegetable Farms”

- Expanding Infrastructure and Maximizing its Potential at Jericho Settlers Farm

Mark Fasching and Christa Alexander run Jericho Settlers Farm where they grow “good food year round” in Jericho, Vermont. Like many, they started out with a garden and roadside stand and continually expanded to growing over 30 acres of vegetables with 18 greenhouses. As their business expanded over the years, so did their infrastructure needs. …

Mark Fasching and Christa Alexander run Jericho Settlers Farm where they grow “good food year round” in Jericho, Vermont. Like many, they started out with a garden and roadside stand and continually expanded to growing over 30 acres of vegetables with 18 greenhouses. As their business expanded over the years, so did their infrastructure needs. …Continue reading “Expanding Infrastructure and Maximizing its Potential at Jericho Settlers Farm”

- Natural Light in the Packshed at High Meadows Farm

Howard Prussack of High Meadows Farm in Westminster West, Vermont grows 7 acres of vegetables and wanted to improve his vegetable washing space. He imagined a bright and warm space instead of the dark and cool dairy barn they were working out of. With a goal of creating a fun and happy place to work, …

Howard Prussack of High Meadows Farm in Westminster West, Vermont grows 7 acres of vegetables and wanted to improve his vegetable washing space. He imagined a bright and warm space instead of the dark and cool dairy barn they were working out of. With a goal of creating a fun and happy place to work, …Continue reading “Natural Light in the Packshed at High Meadows Farm”

- A Three-Season Structure Keeps the Momentum at Flywheel Farm

Ansel Ploog and Justin Cote run Flywheel Farm in Woodbury, Vermont. They wholesale 2 acres of organic vegetables to local co-op stores and through a regional distributor. When starting their farm in 2012, they understood they needed a spot to wash and pack their produce, undercover and off the ground. They chose to go with …

Ansel Ploog and Justin Cote run Flywheel Farm in Woodbury, Vermont. They wholesale 2 acres of organic vegetables to local co-op stores and through a regional distributor. When starting their farm in 2012, they understood they needed a spot to wash and pack their produce, undercover and off the ground. They chose to go with …Continue reading “A Three-Season Structure Keeps the Momentum at Flywheel Farm”

- Top 5: Working with Contractors on a Postharvest Project

Key Takeaways Introduction Construction projects are both exciting and daunting. There’s great joy in dreaming about a new space or a renovated work area, but there can be a long windy path full of dread and stress between what you have now and what you hope to have in the future. Working with a contractor …

Key Takeaways Introduction Construction projects are both exciting and daunting. There’s great joy in dreaming about a new space or a renovated work area, but there can be a long windy path full of dread and stress between what you have now and what you hope to have in the future. Working with a contractor …Continue reading “Top 5: Working with Contractors on a Postharvest Project”

- Duijndam Machines – Used Equipment from Europe

Way back in 2019, we visited Duijndam Machines in The Netherlands. We had heard from growers in the northeast about this fantastical place where used equipment from European growers goes, not to die, but to be reborn. We had to see it for ourselves. And to bring home some video of our tour. The video …

Way back in 2019, we visited Duijndam Machines in The Netherlands. We had heard from growers in the northeast about this fantastical place where used equipment from European growers goes, not to die, but to be reborn. We had to see it for ourselves. And to bring home some video of our tour. The video …Continue reading “Duijndam Machines – Used Equipment from Europe”

- Easy Breezy Three Season Packshed at Stout Oak Farm

Kate Donald began farming at Stout Oak Farm in Brentwood, NH in 2012. As the farm grew she quickly realized they could only handle one, or maybe two infrastructure projects at a time. Much of these improvements went into production practices, and greenhouses that clearly penciled out to be wise investments in the farm. Now, …

Kate Donald began farming at Stout Oak Farm in Brentwood, NH in 2012. As the farm grew she quickly realized they could only handle one, or maybe two infrastructure projects at a time. Much of these improvements went into production practices, and greenhouses that clearly penciled out to be wise investments in the farm. Now, …Continue reading “Easy Breezy Three Season Packshed at Stout Oak Farm “

- New Metal Building from Scratch at Hall Brook Farm

Pheonix and Megan O’Brien of Hall Brook Farm purchased their farm in Thorndike, Maine in 2016, and are growing over 20 acres of vegetables with over ⅓ acre in high tunnels. They have experienced rapid growth of the business in the last few years. In 2020 they had gross sales over $250,000 which expanded in …

Pheonix and Megan O’Brien of Hall Brook Farm purchased their farm in Thorndike, Maine in 2016, and are growing over 20 acres of vegetables with over ⅓ acre in high tunnels. They have experienced rapid growth of the business in the last few years. In 2020 they had gross sales over $250,000 which expanded in …Continue reading “New Metal Building from Scratch at Hall Brook Farm”

- The Next Chapter: Renovating a Barn to Sustain Indian Line Farm

Elizabeth Keen and her husband Al have been farming at Indian Line Farm in Great Barrington, MA for over 25 years. After taking a sabbatical in 2016, they had the realization that after 10-15 years “just running the farm” it was time that some things needed to change to make the farm more sustainable in …

Elizabeth Keen and her husband Al have been farming at Indian Line Farm in Great Barrington, MA for over 25 years. After taking a sabbatical in 2016, they had the realization that after 10-15 years “just running the farm” it was time that some things needed to change to make the farm more sustainable in …Continue reading “The Next Chapter: Renovating a Barn to Sustain Indian Line Farm “

- “Dry Cleaning” on Produce Farms: Alternatives to Using Water & Detergents

Key points: Related posts: Sharpening the Edges: Wash/Pack Efficiencies in a New Farm Building at Small Axe Farm Washing Machine Greens Spinners: Shopping Advice Backflow Prevention for Produce Farms Farmer’s Favorites: Cleaning Tools Planning an Efficient and Safe Wash/Pack Area

Key points: Related posts: Sharpening the Edges: Wash/Pack Efficiencies in a New Farm Building at Small Axe Farm Washing Machine Greens Spinners: Shopping Advice Backflow Prevention for Produce Farms Farmer’s Favorites: Cleaning Tools Planning an Efficient and Safe Wash/Pack Area - Farmer’s Favorites: Cleaning Tools

As part of our SCRUB Project, we have been demonstrating a wide range of Cleaning Tools for Produce Farms, on-farm with growers. This has opened up the question, “Which one(s) should I buy for this specific cleaning task?” Based on our experience and feedback from partner farms, here are some of our favorites that we’d …

As part of our SCRUB Project, we have been demonstrating a wide range of Cleaning Tools for Produce Farms, on-farm with growers. This has opened up the question, “Which one(s) should I buy for this specific cleaning task?” Based on our experience and feedback from partner farms, here are some of our favorites that we’d … - Patient Pursuit of Packshed Happiness at Ananda Gardens

Patrick Sullivan and Melisa Oliva have been farming for 5 years at Ananda Gardens, a CSA Farm in Middlesex, Vermont. They have been working to grow their farm and improve their wash-pack area as they renovated the 1950s dairy barn that stood on the property. They have 150 CSA members between the fall and spring …

Patrick Sullivan and Melisa Oliva have been farming for 5 years at Ananda Gardens, a CSA Farm in Middlesex, Vermont. They have been working to grow their farm and improve their wash-pack area as they renovated the 1950s dairy barn that stood on the property. They have 150 CSA members between the fall and spring …Continue reading “Patient Pursuit of Packshed Happiness at Ananda Gardens”

- Washing Machine/Greens Spinner Conversion Guide

Greens spinners play a vital role making greens production profitable for the small farm. Some farms find themselves stuck in the middle, where inexpensive, small-scale spinners cause a bottleneck, but it is hard to justify a more expensive industrial, stainless steel, restaurant-style machine. If you are just getting started, we have a full overview of …

Greens spinners play a vital role making greens production profitable for the small farm. Some farms find themselves stuck in the middle, where inexpensive, small-scale spinners cause a bottleneck, but it is hard to justify a more expensive industrial, stainless steel, restaurant-style machine. If you are just getting started, we have a full overview of …Continue reading “Washing Machine/Greens Spinner Conversion Guide”

- Preventing Freezing in Produce Coolers

Occasionally, during longer cold snaps, we receive a lot of questions about storage crops freezing in coolers. This post summarizes some ideas for preventing freezing. Summary Seal up the Cooler Box The main culprit in freezing is most likely infiltration of cold, outside air into the cooler. If you’re seeing freezing in one area, there …

Occasionally, during longer cold snaps, we receive a lot of questions about storage crops freezing in coolers. This post summarizes some ideas for preventing freezing. Summary Seal up the Cooler Box The main culprit in freezing is most likely infiltration of cold, outside air into the cooler. If you’re seeing freezing in one area, there … - Root Washers for Produce Farms

There are many ways to wash root crops on produce farms. This guide covers a range of options from smaller farms washing by hand to larger operations with fully automated wash lines. Watch the Webinar Root Washing Systems with Hans Estrin | VVBGA Webinar Series Spray tables Spray tables are commonly used to rinse bunched …

There are many ways to wash root crops on produce farms. This guide covers a range of options from smaller farms washing by hand to larger operations with fully automated wash lines. Watch the Webinar Root Washing Systems with Hans Estrin | VVBGA Webinar Series Spray tables Spray tables are commonly used to rinse bunched … - Building a Better Greens Bubbler

Introduction Leafy greens are a popular crop among consumers seeking a healthy and nutritious diet year-round. As a crop that is grown close to the ground in a variety of systems, often it is important to remove soil from the leaves before marketing. A relatively high volume dunk tank with several, typically lower volume, follow-on …

Introduction Leafy greens are a popular crop among consumers seeking a healthy and nutritious diet year-round. As a crop that is grown close to the ground in a variety of systems, often it is important to remove soil from the leaves before marketing. A relatively high volume dunk tank with several, typically lower volume, follow-on … - Sharpening the Edges: Wash/Pack Efficiencies in a New Farm Building at Small Axe Farm

A video version of this case study is available here and a printable PDF is available here. Evan Perkins & Heidi Choate own and operate Small Axe Farm in Barnet, Vermont. Together, they have been farming mixed vegetables for over 20 years and have been running Small Axe Farm since 2008. About Small Axe Farm …

A video version of this case study is available here and a printable PDF is available here. Evan Perkins & Heidi Choate own and operate Small Axe Farm in Barnet, Vermont. Together, they have been farming mixed vegetables for over 20 years and have been running Small Axe Farm since 2008. About Small Axe Farm … - Safely Dispensing Sanitizers

Sanitizers used for treating post-harvest agricultural water on produce farms often come in 2.5, 5, or 10 gallon totes. These totes can be cumbersome to pour from resulting in splashing and spilling. These chemicals are also shipped in concentrations that can cause injury. Here are some simple ways of increasing the safety and accuracy of …

Sanitizers used for treating post-harvest agricultural water on produce farms often come in 2.5, 5, or 10 gallon totes. These totes can be cumbersome to pour from resulting in splashing and spilling. These chemicals are also shipped in concentrations that can cause injury. Here are some simple ways of increasing the safety and accuracy of … - Shedding Some Light in the Shed – Lighting for Indoor Work on the Farm

As the days shorten and we turn the clocks back, it may be a great time to think about installing or improving lights in some of our indoor spaces. Maybe you could use a bit more light to see the drill size marking in the workshop. Or, perhaps, you’d like to be able to sort …

As the days shorten and we turn the clocks back, it may be a great time to think about installing or improving lights in some of our indoor spaces. Maybe you could use a bit more light to see the drill size marking in the workshop. Or, perhaps, you’d like to be able to sort …Continue reading “Shedding Some Light in the Shed – Lighting for Indoor Work on the Farm”

- Giving a Dairy Barn New Life at New Leaf Organics

A video version of this case study is available here and a printable PDF is available here. Jill Kopel owns and operates New Leaf Organics in Bristol, Vermont and has over 19 years of farming experience. After many years of growing crops and growing the business she made the decision to invest significantly in her …

A video version of this case study is available here and a printable PDF is available here. Jill Kopel owns and operates New Leaf Organics in Bristol, Vermont and has over 19 years of farming experience. After many years of growing crops and growing the business she made the decision to invest significantly in her …Continue reading “Giving a Dairy Barn New Life at New Leaf Organics”

- Project Planning for Postharvest Efficiency, Profitability & Food Safety (Free 8-Part Packshed Webinar)

The UVM Extension Produce Safety Team has developed a video series focused on postharvest upgrades for your farm. Whether your project is organizing a relatively simple outside wash station or building a full packshed from scratch, we share the principles and practice with examples to help you make the most of it. An outline of …

The UVM Extension Produce Safety Team has developed a video series focused on postharvest upgrades for your farm. Whether your project is organizing a relatively simple outside wash station or building a full packshed from scratch, we share the principles and practice with examples to help you make the most of it. An outline of … - Washing Machine Greens Spinners: Cleaning Tips

Washing machine greens spinners are often used for drying greens on small farms. They do require attention to cleaning and maintenance in order to keep them in sanitary working condition. This blog post highlights some tips to cleaning your greens spinner and provides links to six videos that focus on how to best clean these …

Washing machine greens spinners are often used for drying greens on small farms. They do require attention to cleaning and maintenance in order to keep them in sanitary working condition. This blog post highlights some tips to cleaning your greens spinner and provides links to six videos that focus on how to best clean these …Continue reading “Washing Machine Greens Spinners: Cleaning Tips”

- Spray Tables for Produce Farms

If we apply the principles of hygienic design to a spray table it becomes clear that we should think about the cleanability of the materials and the assembly while also thinking about how the materials will hold up over time with repeated use.

If we apply the principles of hygienic design to a spray table it becomes clear that we should think about the cleanability of the materials and the assembly while also thinking about how the materials will hold up over time with repeated use. - Drains for Produce Farms

This guide provides background on planning for drains and drainage from produce wash and pack areas. Direct drains, floor and spot drains, and trench and gutter drains are discussed. A construction drawing for a trench drain is also provided. Related posts: Summer Twilight Series – Event Schedule Great Lakes EXPO Highlight Video Planning an Efficient …

This guide provides background on planning for drains and drainage from produce wash and pack areas. Direct drains, floor and spot drains, and trench and gutter drains are discussed. A construction drawing for a trench drain is also provided. Related posts: Summer Twilight Series – Event Schedule Great Lakes EXPO Highlight Video Planning an Efficient … - A Guide to Cleaning, Sanitizing, and Disinfecting for Produce Farms

This is a guide to understanding the differences between cleaning, sanitizing, and disinfecting. It is focused on produce farms and is motivated by current concerns over the COVID-19 pandemic. Related posts: Planning an Efficient and Safe Wash/Pack Area Considerations for Fruit and Vegetable Growers Related to Coronavirus & COVID-19 Last Resort Farm Not Stalled by …

This is a guide to understanding the differences between cleaning, sanitizing, and disinfecting. It is focused on produce farms and is motivated by current concerns over the COVID-19 pandemic. Related posts: Planning an Efficient and Safe Wash/Pack Area Considerations for Fruit and Vegetable Growers Related to Coronavirus & COVID-19 Last Resort Farm Not Stalled by …Continue reading “A Guide to Cleaning, Sanitizing, and Disinfecting for Produce Farms”

- Planning an Efficient and Safe Wash/Pack Area

By Chris Callahan, Hans Estrin, and Andy Chamberlin Reading not your thing? We have a free, 8-Part webinar video series that goes into depth on all of the following topics discussed below. Project Planning for Postharvest Efficiency, Profitability & Food Safety Summary Efficiency and food safety are integral parts of running a profitable and viable …

By Chris Callahan, Hans Estrin, and Andy Chamberlin Reading not your thing? We have a free, 8-Part webinar video series that goes into depth on all of the following topics discussed below. Project Planning for Postharvest Efficiency, Profitability & Food Safety Summary Efficiency and food safety are integral parts of running a profitable and viable …Continue reading “Planning an Efficient and Safe Wash/Pack Area”

- Washing Machine Greens Spinners: Shopping Advice

This blog post is for those using or considering a converted washing machine as greens spinner. Background For background information on several different types of greens spinners and general thoughts on using washing machine conversions see this blog post. If you’ve purchased a machine and are ready to convert it, see our Washing Machine/Greens Spinner …

This blog post is for those using or considering a converted washing machine as greens spinner. Background For background information on several different types of greens spinners and general thoughts on using washing machine conversions see this blog post. If you’ve purchased a machine and are ready to convert it, see our Washing Machine/Greens Spinner …Continue reading “Washing Machine Greens Spinners: Shopping Advice”

- Ag Engineering Downloadable PDF Resources

All of our resources are available here on this blog. However, if you are looking for a printed handout, here is a list. These are all of the PDF documents that we share during workshops, meetings, and presentations. All links will open the PDF in a new tab. You may also want to check out …

All of our resources are available here on this blog. However, if you are looking for a printed handout, here is a list. These are all of the PDF documents that we share during workshops, meetings, and presentations. All links will open the PDF in a new tab. You may also want to check out …Continue reading “Ag Engineering Downloadable PDF Resources”

- Greens Washline from China

With innovative tools becoming more available for salad greens production from field prep through harvest, mixed greens are becoming more attractive for farmers. Postharvest handling and wash/pack still causes a bottleneck for many farms. Today we share some knowledge on a piece of equipment recently adopted at Jericho Settlers Farm in Jericho, VT. This Greens …

With innovative tools becoming more available for salad greens production from field prep through harvest, mixed greens are becoming more attractive for farmers. Postharvest handling and wash/pack still causes a bottleneck for many farms. Today we share some knowledge on a piece of equipment recently adopted at Jericho Settlers Farm in Jericho, VT. This Greens … - Wheels Keep Things Rolling at Root 5 Farm

A PDF of this case study is available for download here. Danielle Allen and Ben Dana own and operate Root 5 Farm in Fairlee, Vermont. This organic vegetable farm on the Connecticut River provides over 200 CSA members, farmers market, restaurant, and wholesale customers with local, healthy food. Over 100 different varieties of crops are …

A PDF of this case study is available for download here. Danielle Allen and Ben Dana own and operate Root 5 Farm in Fairlee, Vermont. This organic vegetable farm on the Connecticut River provides over 200 CSA members, farmers market, restaurant, and wholesale customers with local, healthy food. Over 100 different varieties of crops are …Continue reading “Wheels Keep Things Rolling at Root 5 Farm”

- Last Resort Farm Not Stalled by Dairy Barn Conversion

A PDF of this case study is available for download here. Silas Doyle-Burr is managing Last Resort Farm in Monkton, VT, taking over the operations from his parents on the farm he grew up at. The farm was purchased in 1987 and transitioned from dairy farming to vegetable production in 1993. They now grow 26 …

A PDF of this case study is available for download here. Silas Doyle-Burr is managing Last Resort Farm in Monkton, VT, taking over the operations from his parents on the farm he grew up at. The farm was purchased in 1987 and transitioned from dairy farming to vegetable production in 1993. They now grow 26 …Continue reading “Last Resort Farm Not Stalled by Dairy Barn Conversion”

- Vegetable Wash Sinks, Tanks, Tubs and Basins: Upgrades for Efficiency and Ergonomics

A pdf of this blog post can be downloaded here. Produce wash sinks and tanks on vegetable farms consist of several different styles, designs, sizes, and uses. The needs vary from farm to farm but some features to consider are highlighted here. Some common basins for washing vegetables could include the following. Commonly Used as …

A pdf of this blog post can be downloaded here. Produce wash sinks and tanks on vegetable farms consist of several different styles, designs, sizes, and uses. The needs vary from farm to farm but some features to consider are highlighted here. Some common basins for washing vegetables could include the following. Commonly Used as … - Last Resort Farm: Post Harvest Case Study (Video Series)Silas Doyle-Burr is managing Last Resort Farm in Monkton, VT, taking over the operations from his parents on the farm he grew up at. The farm was purchased in 1987, and transitioned from dairy farming to vegetable production in 1993, and now grow 26 different crops split just about evenly retail vs. wholesale. The following …

Continue reading “Last Resort Farm: Post Harvest Case Study (Video Series)”

- Cooler Construction Options – Walls and PanelsThere are many options when it comes to constructing a walk-in cooler, cold room, or warm room for on-farm storage. The main goals for construction of any temperature and humidity controlled space are: Insulate the walls to provide for efficient temperature control against a different outside temperature (which may be a warmer inside space) Seal …

Continue reading “Cooler Construction Options – Walls and Panels”

- Mighty Clean and Comfortable (Video Series)Lisa MacDougall has led Mighty Food Farm through start-up, relocation from rented land to owned land, and now through the construction of a brand-new 60 ft x 90 ft wash and pack shed. She’s done this all while producing a diverse mix of organic vegetables, tree fruit and berries on fourteen acres, now, in Shaftsbury. …

Continue reading “Mighty Clean and Comfortable (Video Series)”

- The BarnHouse: Optimized for Modern Day Vegetable Farming at Footprint Farm

Download the PDF Fact Sheet of this Post Harvest Case Study Here! Taylor and Jake Mendel own and operate Footprint Farm in Starksboro, VT. Starting their own farm in 2013, they now produce pretty much everything except storage potatoes and storage squash with 66 different kinds of vegetables grown in both fields and high-tunnels. Related …

Download the PDF Fact Sheet of this Post Harvest Case Study Here! Taylor and Jake Mendel own and operate Footprint Farm in Starksboro, VT. Starting their own farm in 2013, they now produce pretty much everything except storage potatoes and storage squash with 66 different kinds of vegetables grown in both fields and high-tunnels. Related …Continue reading “The BarnHouse: Optimized for Modern Day Vegetable Farming at Footprint Farm”

- Footprint Farm: Post Harvest Case Study – Video SeriesLooking to upgrade your wash-pack space? Check out this interview with Taylor Hutchison from Footprint Farm talking about their motivations for building a new barn (house!) and including all the features they implemented to make it food safe and efficient. Stay tuned for a written case study, and a downloadable pdf coming soon. The playlist …

Continue reading “Footprint Farm: Post Harvest Case Study – Video Series”

- Hanging Hoses

Having water when and where you need it can make a big difference in vegetable wash station efficiency. Planning for multiple “drops” or spigots around the wash area can make it more convenient to access water where it is needed. Investing in a hose hanger, hose reel or a trolley can help keep the hose …

Having water when and where you need it can make a big difference in vegetable wash station efficiency. Planning for multiple “drops” or spigots around the wash area can make it more convenient to access water where it is needed. Investing in a hose hanger, hose reel or a trolley can help keep the hose … - Bins, Buckets, Baskets & Totes

So you’re starting to farm, or scaling up your production. You hear talk about produce safety and cleanability. You are checking out what other farms are doing and are looking for harvest crates and storage bins. You probably noticed lots of people use many different things. Some use 5-gallon pails, milk crates, muck buckets, some …

So you’re starting to farm, or scaling up your production. You hear talk about produce safety and cleanability. You are checking out what other farms are doing and are looking for harvest crates and storage bins. You probably noticed lots of people use many different things. Some use 5-gallon pails, milk crates, muck buckets, some … - Mighty Clean and Comfortable – A New Wash and Pack Shed at Mighty Food Farm

Download this Postharvest Case Study as a PDF Here! Lisa MacDougall has led Mighty Food Farm through start-up, relocation from rented land to owned land, and now through the construction of a brand-new 60 ft x 90 ft wash and pack shed. She’s done this all while producing a diverse mix of organic vegetables, tree …

Download this Postharvest Case Study as a PDF Here! Lisa MacDougall has led Mighty Food Farm through start-up, relocation from rented land to owned land, and now through the construction of a brand-new 60 ft x 90 ft wash and pack shed. She’s done this all while producing a diverse mix of organic vegetables, tree …Continue reading “Mighty Clean and Comfortable – A New Wash and Pack Shed at Mighty Food Farm”

- Postharvest Resource SurveyWe are seeking input regarding a research and education project with the goal of consolidating postharvest information in a single set of resources. Our proposed project aims to consolidate existing knowledge, best practices, and new developments in postharvest equipment, infrastructure, and buildings into a web-based handbook, workshop curriculum / educational materials and recorded videos. Click …

- Greens Spinners for Farm Use

Download the PDF Fact Sheet Here! Introduction An important factor in growing and selling high-quality salad greens is being able to efficiently wash, cool, and dry the product. The drying step is commonly done using centrifugal force in a spinner. The water is spun off of the greens through a filter basket or other porous …

Download the PDF Fact Sheet Here! Introduction An important factor in growing and selling high-quality salad greens is being able to efficiently wash, cool, and dry the product. The drying step is commonly done using centrifugal force in a spinner. The water is spun off of the greens through a filter basket or other porous … - Spring Cleaning – Farm Cooler Checklist

Whether your winter storage rooms are getting bare or you are making the transition from sweet corn to potatoes, what better time to do a good cleaning and even sanitizing than now? Download this Guide & Checklist as a PDF Housekeeping Start by emptying the room and removing all visible debris with sweeping or vacuuming. …

Whether your winter storage rooms are getting bare or you are making the transition from sweet corn to potatoes, what better time to do a good cleaning and even sanitizing than now? Download this Guide & Checklist as a PDF Housekeeping Start by emptying the room and removing all visible debris with sweeping or vacuuming. …