![]() Download an updated PDF version of this information here!

Download an updated PDF version of this information here!

Smooth and cleanable surfaces are an important aspect of areas where produce is washed, packed, stored and processed. Many farms are investing in renovations and expansions of these areas and are seeking materials to meet this “finish surface” need regardless of specific regulation. Meanwhile, food processing companies are often required to incorporate these materials due to regulation. This is a summary of some of the finish surface materials that are available, their pros, cons and pricing at this time.

Notes:

- These are not necessarily compliant for food contact surfaces; they are meant to be finish materials for areas where food is being washed, packed or stored. The general guidance is “smooth and cleanable.” Check with the appropriate local and/or state enforcement agency to confirm applicability to your project.

- The prices listed are material cost only. The products differ in with regard to installation labor. For example, flexible sheathing like FRP will require some sort of rigid wall material to mount to where as rigid panels such as Trusscore, Extrutech and Utilite can be installed on top of furring strips. No installation costs have been captured in the prices listed.

- Links to manufacturer info are included. Most manufacturers sell via distribution channels. Check with your local building supply company for availability and current pricing. As with most materials, higher volume purchasing generally results in lower unit costs.

- The pricing on these materials is quite variable depending on the source, when you obtain a quote, the quantity being ordered and how it is delivered. The listed price is the best information available at the time of writing. Shop around and obtain quotes from several distributors.

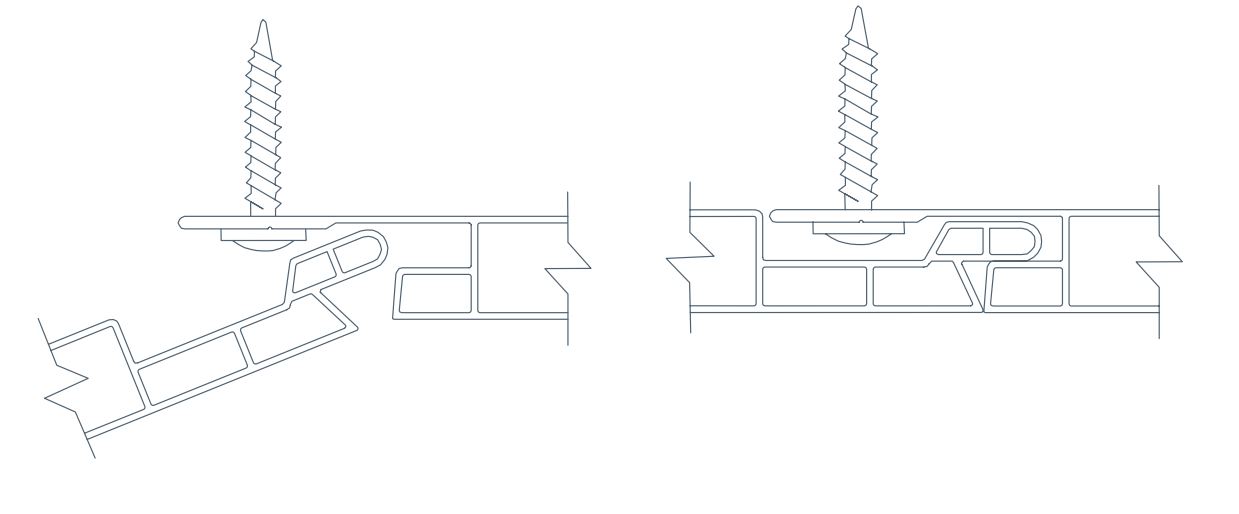

Several manufacturer’s use panel locking mechanisms such as the tongue and groove system found in Trusscore. This provides for a smooth finish and hides the fasteners.

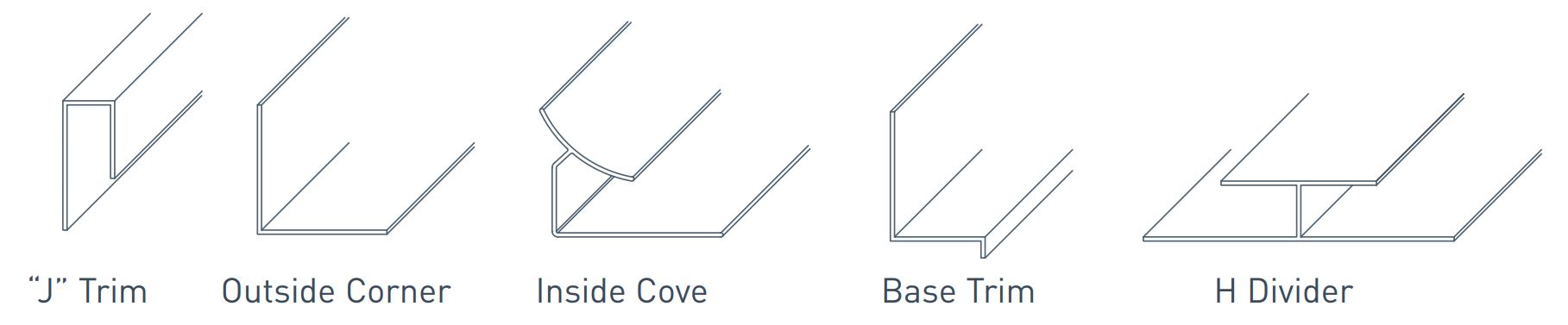

Common shapes of available trim options to cover and seal all edges and seams. This keeps water from seeping behind the finish surface and entering the walls which can lead to molds and mildews and structural damage. - Most manufacturer webpages include an easy to find, specific, installation guide for their product that will be helpful in guiding installation.

- FRP or Trusscore wall panels use H channel trim between pieces and top, bottom and corner trim pieces too. All of these are calked in place to ensure a moisture proof seam. Follow the manufactures installation procedures.

*Update: WallTuf Paneling is not distributed to the Vermont region! It can be ordered through Gilfoy Distributing in MA or Guardian Building Products in ME.

*Wallboard Supply Company in Williston VT is a source for FRP, Trusscore, and roofing materials. Check in with Poulin or Curtis Lumber for availability as well.

Fiber Reinforced Plastic: Installation Tips

FRP requires a backing board and either adhesive or rivets for sound assembly. Foam board doesn’t take most adhesive very well. Some foam board adhesives are available in tubes for application in long, thin beads. The FRP adhesive is in tubs for application with a trowel for wider bonding surfaces.

Liquid Nails has a product designed for this application. https://www.liquidnails.com/products/fibergrass-reinforced-panel-adhesive#platform-statement. $22/gal at Home Depot.

When installed correctly with attention to detailed on the trim pieces, caulking etc a vapor barrier is not required as this material acts as a moisture plane.

FRP installation is actually a tricky thing to get right and that’s one reason we tend to see more people using rigid finish surfaces like Trusscore and metal roofing which use more common building techniques such as fasteners.

Trusscore Installation

Trusscore has a website and video walking you through how to install this material. Farmers who have used this material like it as it costs a little more upfront but does not require a backer board and installs fairly quickly reducing either their own, or hired labor. A few key points:

- It goes up very similarly to vinyl siding.

- It can be installed horizontally onto studs or vertically onto furring strips or strapping depending on the look and space of your room it may produce less seams to go vertical.

- Caulking should be used between the seams

- There are trim pieces to use on the tops, bottoms, ends and corners to get a clean install and a waterproof surface.

User Reviews

Many farms are loving the upgrade to these smooth and cleanable materials. To see their projects check out our Post Harvest Case Studies.