Vegetable growers are seeking tools to improve flexibility and efficiency in the packshed. The AZS Rinse Conveyor is becoming a popular piece of equipment to meet the need to rinse off a variety of crops.

Table of Contents

Overview

Common Uses

Cost

User Reviews

Use as a Bin Washer

Contact information

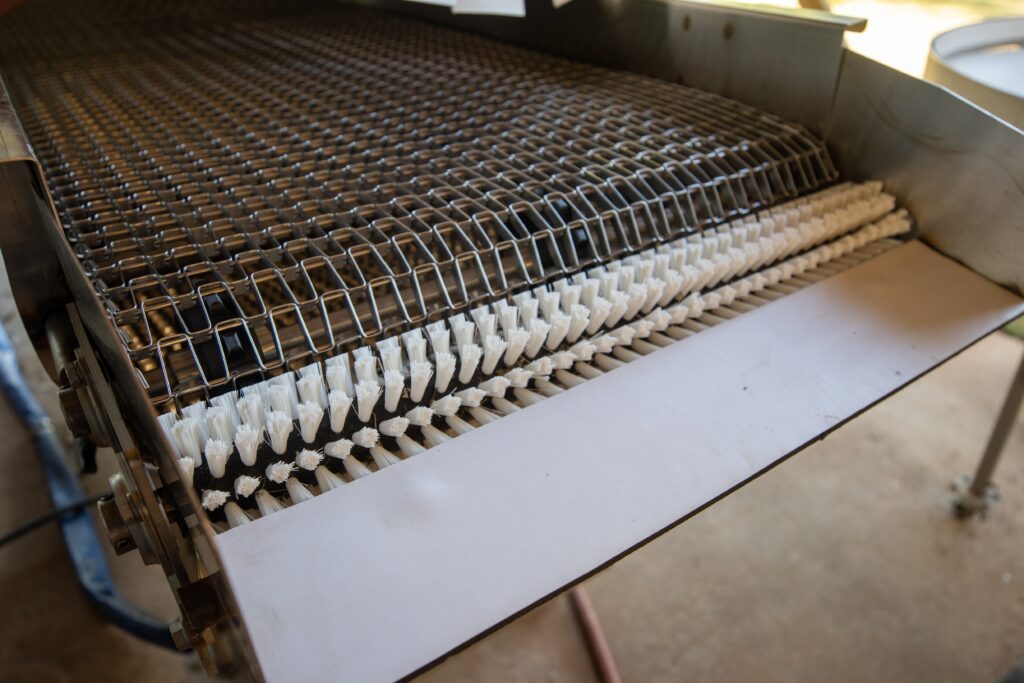

This machine is designed and manufactured by AZS Brush Washer Company (Ephrata, PA, (717) 733-2584) . It consists of a stainless steel mesh conveyor belt over a tank of water that rinses the produce as it moves through the machine. It has a wide range of water flow, pressure, and belt speed to adjust based on the crop being washed or the soil type of your farm. It’s constructed of stainless steel and is covered to minimize over-spray.

Common Uses

This machine is ideal for washing bunched crops including, but not limited to: scallions, onions, leeks, carrots, beets, cilantro, radishes, kale, or turnips. These crops can be passed through both pre-banded or laid out individually before bunching.

Loose crops like cucumbers, peppers, zucchini, summer squash or winter squash can effectively be washed with this machine.

Washing root crops including carrots, potatoes, sweet potatoes, beets, parsnips, or Jerusalem artichoke is also effective. Some growers who are washing large volumes of roots (pallet bins) or have a really sticky soil type (clay) have found success by passing the product through a barrel washer to tumble and agitate the crop first, then use this machine as a final rinse. Excess soil from a mechanically harvested crop can overwhelm the machine with mud and require clean out part way through the session.

Typically greens are most effectively washed in dunk tanks, however we have heard of some growers having good luck using this machine on head lettuce or even laid loose in crates.

Another benefit of a wash line like this is the effect of hydrocooling your crops. Rinsing produce with a cool supply of water (from a cold well) or even pre-chilled water will rapidly remove the field heat from your crops and improve the quality and shelf life.

The rinse conveyor also works well, in addition to potential hand scrubbing, as a bin washer to batch rinse all of the totes or harvest lugs on the farm. It is important to include a “clean break” between produce rinsing and bin washing (more on that below).

Utility Requirements

The Rinse Conveyor uses 240v (32A) single phase power and requires 5 GPM (gallons per minute) of water supply at 30 psi or higher.

Operation of this machine works best with 2-3 people. One person to load the machine, and 1-2 to sort/pack out of.

Cost/Benefit

If you order directly through the manufacturer you can have a machine built as custom order to better fit the needs of your farm. They are available in both 16” or 24” wide models and there are a few options for pump selection.

The base cost of this machine is $9,000-12,200.

Additional equipment also offered by AZS which pairs nicely to build a complete wash line to minimize bottlenecks. This may include the use of a: pressure washer wand, bin dumper, soak tank/elevator, barrel washer, sorting conveyor, rotating packing table, or sizers.

A wash line is no doubt a large investment in the farm and you’ll have to run the numbers for yourself to calculate your return on investment. We recently went through a “back of the napkin” calculation with a grower who currently has 6-9 people working in their wash pack throughout the season. If we estimated that they could shrink the labor demand by 3 people, 4 hours each day, 5 day week for 20 weeks of the year at $15/hr they would have spent $18,000 in labor. Based on that math it would justify the expense with-in one season of use! After realizing this the grower decided he should look a little closer at investing in his wash/pack operation.

User Reviews

We have showcased a variety of use cases on farms across the nation. Each farm noted below has a full write up on how they incorporate this machine on their farm.

Sassafrass Creek Farm Leonardtown, MD

Native Son Farm Tupelo, MS

Piccadilly Farm, Winchester, NH

Jericho Settlers Farm Jericho, VT

Hall Brook Farm Thorndike, ME

Using a Rinse Conveyor for Bin Cleaning

In other posts, publications, and videos, we’ve noted some of the pros and cons of rinse conveyors like the AZS machine. One of the things several growers have noted about the machine is that it can make bin cleaning a lot easier. It can be a great way of dealing with a tedious job. But, before you jump right in, take a moment to check out some of the best practices we’ve collected below.

Key Take-Aways

- Use a Clean Break

- The Machine May Not Clean Completely

- Cleaning Involves a Detergent

- Adjust Sanitizer Concentration as Needed

Use a Clean Break

Remember Module 6 of the PSA Grower Training? No? Ok, you’re forgiven. But one key point was the idea of a “clean break.” A clean break, in simple terms, is a break in your production flow when you clean and sanitize. It is meant to separate one lot of produce from another or, in this case, one use from another. In this case, we want to use a clean break to separate produce meant for market from bins being cleaned. What does it all mean? It means, you should stop, clean and sanitize your rinse conveyor between the two uses. We want to avoid any contamination that a given lot of produce may have had from being spread onto a given lot of bins. And vice versa, we don’t want any contamination from the bins to find its way onto produce. If you are looking for cleaning tools to aid in the maintenance of your machine we recommend some here.

The Machine May Not Clean Completely

So, by now, you’ve opened up your PSA Grower Training Manual to refresh your memory on Module 6, right? No? Ok, no worries. Two other key principles in that section were (1) the steps involved in cleaning and (2) the difference between cleaning and sanitizing. The PSA covers both of these with a nice fact sheet. The take home for this specific purpose is that those bins you’re sending through the rinse conveyor may need (1) some extra special attention beyond the ‘cleaning’ the conveyor offers and (2) you need to include a detergent in the rinse conveyor to adequately clean the bins. A first step in any bin washing should be to do a quick ‘once over’ on each bin to see just how much cleaning is needed. A bin with heavy soil, visible filth, and certainly any sign of feces or other contamination needs to have a dedicated scrub down and sanitization ideally far away from where you are handling produce.

Cleaning Involves a Detergent

Now that we’ve reviewed Module 6 in the previous two points, you know where we are headed next. That’s right, if we’re talking about cleaning with water, we also need to be sure we’re including a detergent. Water is great, it has superpowers as a solvent and makes the world go ‘round. But for our purposes we need to bring in another superpower, the power of a detergent. We cover all the greatness of detergents in a blog post elsewhere. The key here is, if those bins are seeing water they need to also see some detergent. The machine’s spraying action may be sufficient for the “scrubbing” that is required in cleaning, but a detergent needs to be in the mix.

Adjust the Sanitizer Concentration as Needed

If you’re using the rinse conveyor for produce rinsing and have a sanitizer injector or other dosing system for that use, remember that this is a different use. When rinsing produce, sanitizer is added to achieve a concentration specific for “postharvest water treatment”. This is meant to maintain the quality of the water. It prevents cross contamination from one piece of produce to another piece of produce. When you are using the machine to clean and sanitize bins, you need to adjust the sanitizer concentration to the level required for “sanitizing food contact surfaces” which is usually higher. More info on the different concentration levels for different sanitizers and different uses is available in our post on cleaning, sanitizing, and disinfecting. If you need some help figuring out the dose to achieve a certain concentration, check out our online sanitizer calculator.

See Harvest Totes Get Rinsed Off Using This Machine

Indepth Overview of the Machine

Contact the Manufacturer

AZS Brusher Equipment

821 Crooked Ln

Ephrata, PA 17522

Phone: (717) 733-2584

Looking for other wash/pack equipment ideas?

Consider reading Root Washers or Greens Spinners Produce Farms.