Josh Carter is the manager of the market garden at Shelburne Farms. They grow three acres of certified organic fruit, vegetables and flowers while supporting an educational mission. They wanted to eliminate a bottleneck in their postharvest systems of hand washing roots with hoses and power washers, turning them around by hand or in crates. This led them to invest in a barrel washer for their farm.

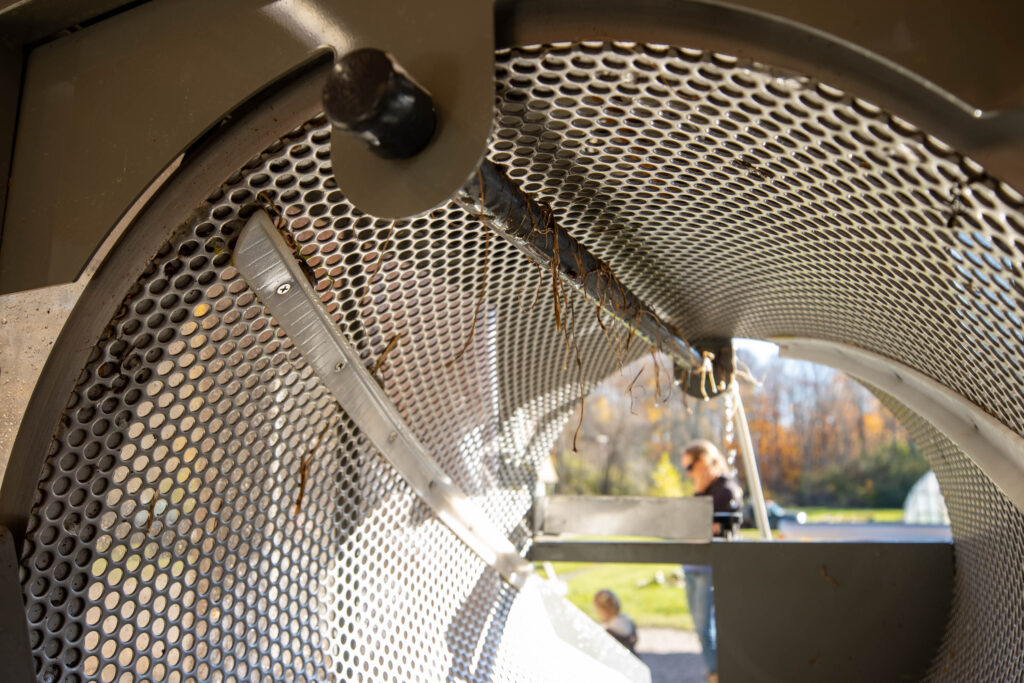

They chose to purchase a Univerco Barrel Washer due to its compact size. This makes it easy to store when not in use, which for them is more often than not. This farm typically washes small batches of roots so they didn’t need a large machine for bulk handling of storage crops.

The cost of the machine was $8,000 (2021) delivered to Shelburne, Vermont. They opted for a variable speed motor which was an ad-on.

Josh expects this piece of equipment to hold its value as it’s well-built using both steel and stainless steel. He’s looking forward to the efficiency it will bring along with labor savings and improved staff happiness.

Upon delivery, it needed some adjustments as the belt was slipping and there were some wear plates that they ended up removing because the drum was binding with them in. It has been reliable after these initial set-up adjustments.

Josh notes that they harvested their potatoes when it was dry, which helps to minimize the amount of soil on them to begin with. Their soil type is fairly sandy which also helps to make washing roots easier.

Potential improvements

This barrel washer is a fairly new item, and Josh notes that the exit shoot is a little short, and the slide gate is a little low. They added an additional shield using a clamp to keep the crops from falling out.

The wheels don’t swivel, so that makes it difficult to move around, needing to drag it at times. It would be nice if, at least, one side swiveled.

Additional Options

At Shelburne Farms they are using-single pass water. A constant flow of a fresh spray to the crop. There is an option to purchase a basin with a recirculating pump if you have a limited amount of water or are washing fairly clean produce to begin with.

See it in Action

Final Thoughts

“It’s a nice product that fits our scale, perfect for a 3-5 acre mixed vegetable farm.”

Josh Carter

Looking for other Root Washing Options?

Share This Post

Acknowledgements

This project was supported by the Food and Drug Administration (FDA) of the U.S. Department of Health and Human Services (HHS) as part of a financial assistance award 02200-FSMA-24-01 totaling $30,000 with 100 percent funded by FDA/HHS. The contents are those of the author(s) and do not necessarily represent the official views of, nor an endorsement, by FDA/HHS, or the U.S. Government.