Hygienic design intentionally creates or improves spaces and equipment so they can be cleaned and sanitized as appropriate.

This post, associated PDF guide and checklist (PDF and Excel, instructions) are tools we developed to help apply hygienic and sanitary design practice on produce farms.

We also collaborated on a video introduction to hygienic design with colleagues at Michigan State University.

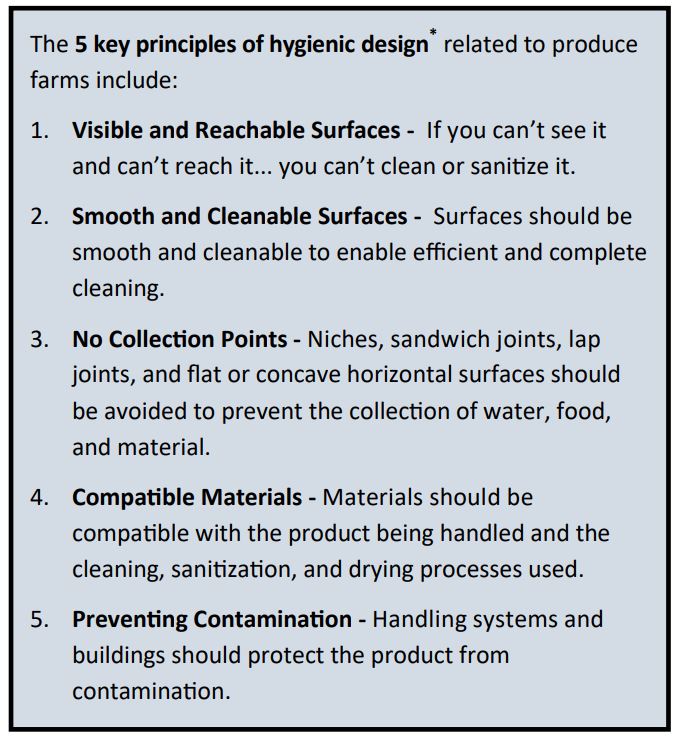

These tools cover the five key principles of hygienic design for produce farms:

- Visible and Reachable Surfaces

- Smooth and Cleanable Surfaces

- No Collection Points

- Compatible Materials

- Preventing Contamination

You Can Learn About Hygienic Design from Our YouTube video playlist

Introduction

The purpose of hygienic design is to intentionally create or improve spaces and equipment so that they can be cleaned and sanitized as appropriate. The motivation for this is that microorganisms such as human pathogens are small and can persist in even the tiniest of spaces in the right conditions. The role of hygienic design is to prevent this by incorporating, often passive, design features into equipment and buildings to minimize or eliminate harborage of human pathogens when combined with appropriate cleaning, sanitizing, and drying procedures.

Visible and Reachable Surfaces

A surface must be visible and reachable in order to be adequately maintained and cleaned. This does not mean the surface must always be accessible. For example, often drive components of a machine have protective covers to prevent worker injury. However, these covers should be able to be removed to allow for cleaning of equipment on a regular basis.

If tools are required to partially disassemble a machine prior to appropriate cleaning, the tools should be clearly marked for that purpose, a standard operating procedure (SOP) should be developed for the steps involved, and employees responsible for the process should be trained accordingly.

It may be helpful to purchase a mirror for inspection and a flashlight to improve your ability to see some of the far corners inside and under equipment.

Cleaning procedures may require partial disassembly of equipment for adequate cleaning of food contact surfaces. If tools are required to partially disassemble a machine prior to appropriate cleaning, the tools should be clearly marked for that purpose, a standard operating procedure (SOP) should be developed for the steps involved, and employees responsible for the process should be trained accordingly.

It may be helpful to purchase a mirror for inspection and a flashlight to improve your ability to see some of the far corners inside and under equipment.

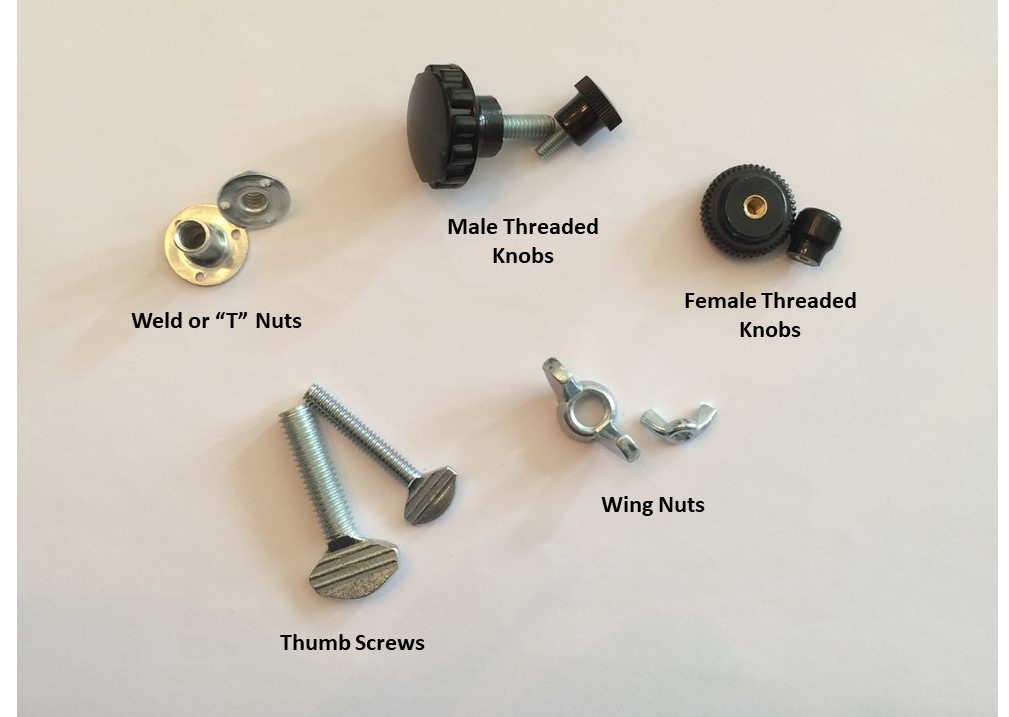

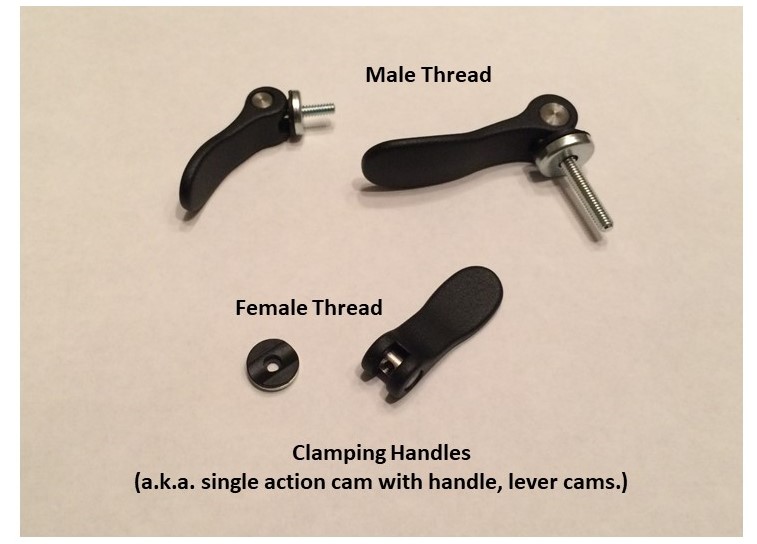

To make disassembly and cleaning easier, it may be possible to replace nuts and bolts on guards and shields with other “tool-free” fasteners (e.g., weldnuts, weldstuds, wingnuts, camlocks, or twist locks) that are easier to remove or operate. Some fasteners allow for disassembly without resulting in loose parts, which can reduce mechanical contamination risk. Consult with the manufacturer and the equipment manual before making changes. Always disconnect power, shut off equipment water supply, and de-energize all other relevant utilities before cleaning. Let others in the work area know that you will be cleaning the machine and that the utilities are off for a good reason and should not be turned back on until the cleaning is complete. Consider implementing a lock-out, tag-out (LOTO) procedure and training employees in it.

Smooth and Cleanable Surfaces

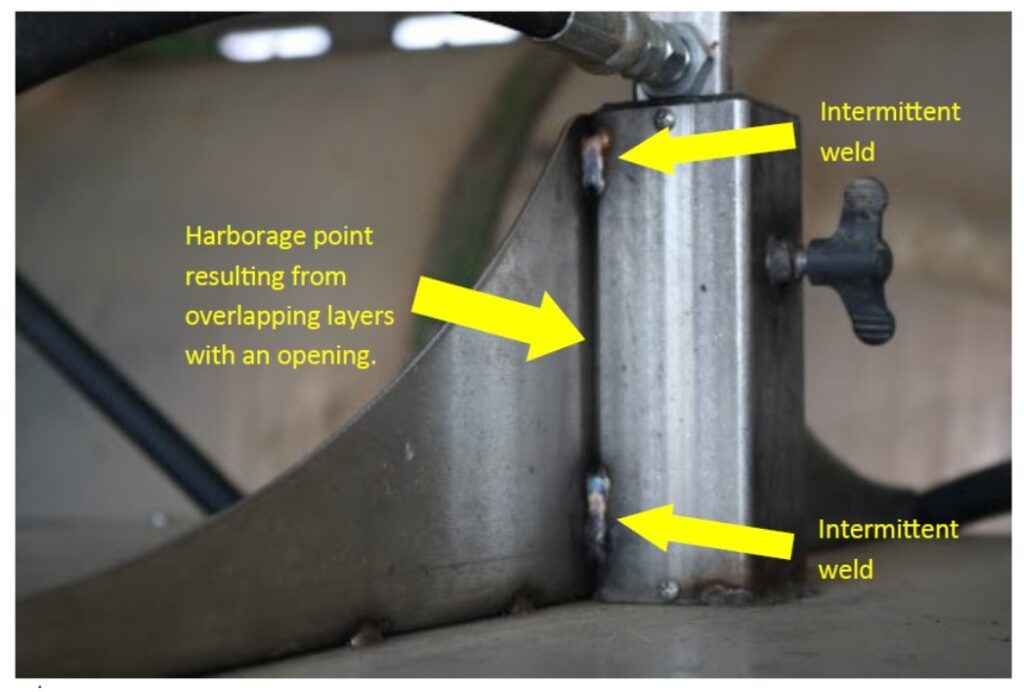

Often the best hygienic design elements are passive. Investment in a passive feature now will make things easier later and save money over time. Smooth, filleted or rounded welds at the corner of tanks lead to more effective and efficient cleaning. Favor continuous welds over intermittent welds. Grind and sand the welds smooth to improve cleaning. Avoid hollow member construction and areas with sandwiched or lapped layers of material such as the space inside the top edge of tank formed by rolled or crimped sheet metal. Another common practice is to avoid flat horizontal surfaces in structural members of a machine opting for circular tube construction or rotated square stock instead. Rotating square stock to a 45° angle reduces areas where water, food and other material can collect.

No Collection Points

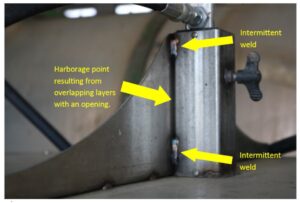

A key principle of hygienic design is avoiding spaces where water, food, and other material can collect. This includes niches and sandwich joints. Sandwich joints are common where two surfaces are brought together in an assembly and are not completely sealed with a continuous weld that is then ground smooth. A narrow harborage site results between two surfaces. These harborage sites allow water and solids to accumulate. This provides conditions that support the growth of microorganisms including human pathogens.

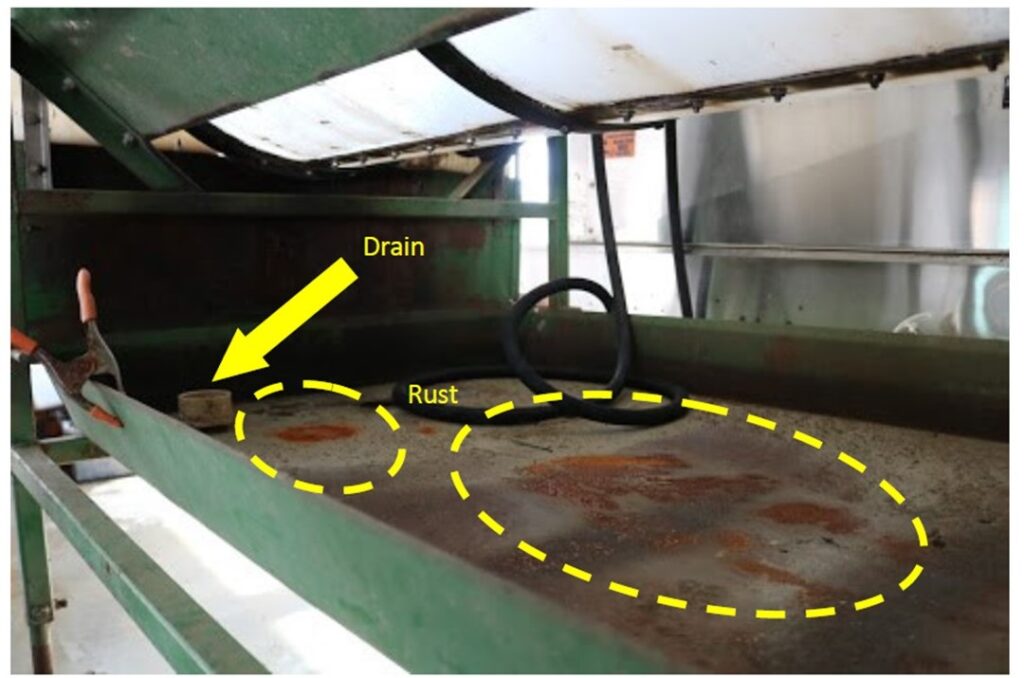

Hollow spaces, such as the interior of a tube or square stock structural members, can also become harborage locations if they are not completely sealed. A little bit of seepage of water and organic matter with each day of produce washing can accumulate in a hollow space over time. These spaces hold moisture and also promote rusting of steel equipment.

Collection points are, unfortunately, very common on produce equipment. They result from assembly practices that are favored because they are relatively inexpensive and easy. Some ways to address existing collection points may include adjusting the legs on equipment to achieve a slight pitch to encourage flow to a drain, re-breaking (bending with cross diagonals) or replacing sheet metal collection pans with more aggressive drain pitch, adding bottom drain ports to equipment with difficulty draining from existing side ports, and including a squeegee and towel dry step to a cleaning SOP for, particularly challenging areas.

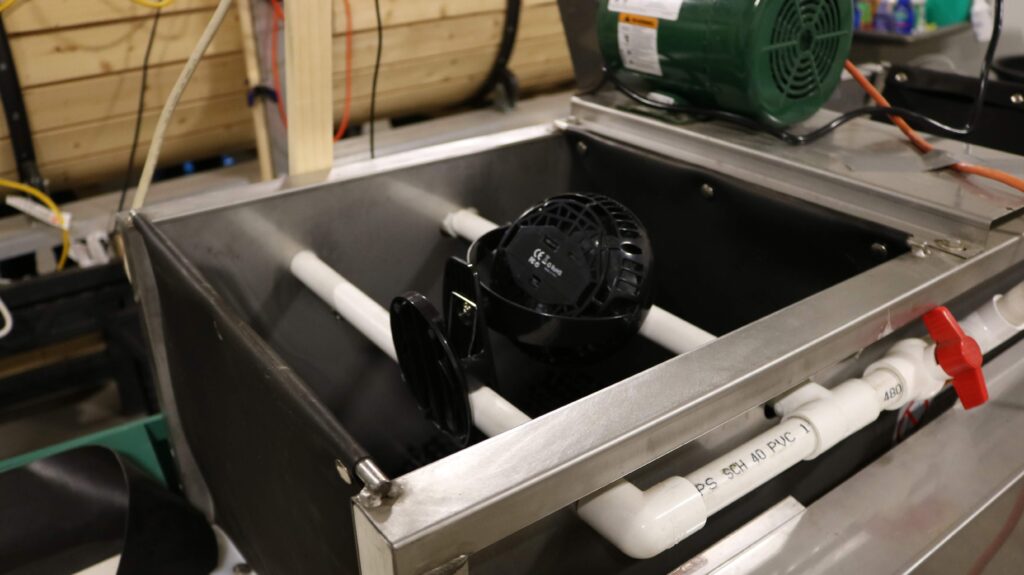

Fans and blowers can be very helpful in promoting drying of equipment after cleaning and sanitizing. This drying step is very important as a means to remove the availability of water that can promote pathogen survival and growth. The wash/pack area can be warmed slightly with a space heater to reduce the relative humidity of the air and increase the air’s capacity to carry water away as vapor which speeds and deepens the drying. Floor fans or blowers designed for drying floors and carpets are portable and inexpensive tools for supplying large amounts of airflow to the inside of equipment that may otherwise be difficult to dry. It is also important to provide some ventilation of the wash/pack area to encourage air exchange. The air that is made humid from drying equipment needs to be exhausted outside and fresh, relatively dry air needs to be drawn in from outside. The relative humidity of the air can be reduced by heating to improve the rate and efficacy of drying.

Special cleaning tools may be helpful in reaching far corners that are not easily accessible or for fitting into small areas that are otherwise hard to clean. It may take some experimentation and ingenuity to find the right tool. Ladders may also be helpful for getting above the equipment to inspect for cleanliness and to complete the cleaning process. Finally, it may be helpful to turn certain machines on their side or upside down to access certain hard to reach areas. Take care not to place any food contact surfaces on the ground or result in other contamination in the process. Some of this work may require a second or third partner to be completed safely.

Compatible Materials

The materials used in the construction of equipment must be compatible with both the product the machine is handling and also the cleaning, sanitizing, and drying procedures used. Appropriate materials are generally smooth, durable, corrosion-resistant, and impermeable to water. This includes being compatible with cleaners and sanitizers and generally favors stainless steel and food-grade plastics since these materials have been developed specifically for this type of use.

Incompatible materials will degrade more quickly due to nicks, cracks, corrosion and other wear. Painted carbon steel may not hold up well to water and eventually the paint will flake and the steel will rust. Both of these could become mechanical and/or chemical contaminants and will result in the surfaces not being cleanable.

Consider the chemicals in the cleaners and sanitizers you use relative to the materials in your equipment. Think beyond the obvious food contact surfaces and consider rubber seals, bearings, drive components, electrical housings, etc.

Preventing Contamination

The siting, layout, construction, and materials used in handling equipment and buildings should prevent the contamination of product from the environment, the building, the equipment, people, vehicles, and by cross-contamination among the product itself.

This includes excluding animals that may introduce fecal or other contaminants. Passive measures can be very effective at excluding birds (rafter netting) and rodents (wire mesh or hardware cloth in framing). Maintaining a clean area around the building helps to reduce attraction and cover for wildlife pests. Removing culls from packing area daily and locating away from the wash/pack area, trimming grass, and keeping items in storage at least 6” from the walls can all help to reduce attraction and cover for pests. Exterior baiting and exterminating can be used as a final option.

Evaluating Equipment and Buildings for Hygienic Design

The principles of hygienic design can be readily applied to any piece of equipment or building. The accompanying checklist has been developed specifically for farm-based produce handling equipment and buildings. It is based on other, more extensive guides from the processing industry. This checklist provides a focused evaluation against the principles outlined above. The checklist is available as a spreadsheet that will sum the ratings based on the reviewer’s assessment. It is also attached as the last pages of this guide as a hand-written sheet.

Conclusion… It is Never Done.

Hygienic design is a process of continual improvement. This guide and the checklist are meant to aid in evaluating equipment and buildings as a “snapshot” of one point in time. The act of reviewing the equipment or building should motivate a plan for improving certain areas of design. Once those changes are made and put into practice, the team can review the equipment again. These checklists can also be helpful in identifying either preventive or reactive maintenance of equipment and buildings that may not be obvious during normal operation. A team approach to review is encouraged to provide multiple perspectives from multiple users with different skills and ideas.

Share This Post

https://go.uvm.edu/hygienicdesign

References

- AMI Equipment Design Checklist. https://www.meatinstitute.org/ht/a/GetDocumentAction/i/97261, also available as an Excel sheet.

- Callahan, C., & Chamberlin, A. (2018, May 21). Floor Design for Vegetable Wash, Pack and Storage Areas. University of Vermont Extension. Retrieved from http://go.uvm.edu/floors

- Callahan, C., & Chamberlin, A. (2018, July 21). Greens Spinners for Farm Use. University of Vermont Extension. Retrieved from http://go.uvm.edu/greensspinners

- Callahan, C., & Chamberlin, A. (2017, September 29). Smooth and Cleanable Surfaces. University of Vermont Extension. Retrieved from http://go.uvm.edu/smoothnclean

- Callahan, C., & Chamberlin, A. (2017, October 9). Rats (and Other Rodents). University of Vermont Extension. Retrieved from http://go.uvm.edu/ratsCommercial Food Sanitation. Food Sanitation Institute. Hygienic Design Training: Participant Workbook. New Orleans, LA. (June 19-21, 2018). http://www.commercialfoodsanitation.com/documents/

- Commercial Food Sanitation. Food Sanitation Institute. Produce and Fruit Equipment Design Checklist. (June 4, 2018). http://www.commercialfoodsanitation.com/v2/wp-content/uploads/2018/06/Download-Equipment-Design-Checklist-Produce-and-Fruit-2018.06.04.xlsx

- Commercial Food Sanitation. Food Sanitation Institute. Produce and Fruit Facility Design Checklist. (June 4, 2018). http://www.commercialfoodsanitation.com/v2/wp-content/uploads/2018/06/Download-Facility-Design-Checklist-Produce-and-Fruit-2018.06.04-1.xlsx

- Holah, J., & Lelieveld, H. L. M. (Eds.). (2011). Hygienic Design of Food Factories. Woodhead Publishing.

- IFAP Fresh Cut Design and Buying Checklist: http://foodsafety.psu.edu/angel/fssbook/unit_2/module_7/docs/IFPAEquipChecklist.pdf

- Jowitt, R. (Ed.). (1980). Hygienic Design and Operation of Food Plant (American). The AVI Publishing Company, Inc.

- Lopez-Garcia, A., & Barbosa-Canovas, G. V. (2005). Food Plant Design (1st ed.). CRC Press.

- Schmidt, R. H., & Erickson, D. J. (2017). Sanitary Design and Construction of Food Equipment (FSHN0409). University of Florida – IFAS Extension. Retrieved from https://edis.ifas.ufl.edu/pdffiles/FS/FS11900.pdf

- Troller, J. A. (n.d.). The Sanitary Design and Construction of Food Production Facilities. In Food Engineering (Vol. IV). Retrieved from https://pdfs.semanticscholar.org/bc2b/c99d98578ec793a7dfcca6685dbca7c24505.pdf

Acknowledgments

Funding for this statement, publication, press release, etc. was made possible, in part, by the USDA Northeast Sustainable Agriculture Research and Education program through award LNE19-375, by the Food and Drug Administration through grant PAR-16-137 and by the USDA’s National Institute of Food and Agriculture through the Specialty Crops Research Initiative under award number 2016-51181-25402 and Food Safety Outreach Program award 2016-70020-25792 accession 1010528. The views expressed in the written materials or publications and by speakers and moderators do not necessarily reflect the official policies of the U.S. Department of Health and Human Services or the U.S. Department of Agriculture; nor does any mention of trade names, commercial practices, or organization imply endorsement by the United States Government.