There are many options when it comes to constructing a walk-in cooler, cold room, or warm room for on-farm storage.

The main goals for construction of any temperature and humidity controlled space are:

- Insulate the walls to provide for efficient temperature control against a different outside temperature (which may be a warmer inside space)

- Seal corners and seams to prevent air and rodent infiltration

- Protect framing and insulation with smooth, cleanable materials and vapor barrier to prevent moisture and condensation inside the walls.

The resources below provide an overview of common cooler wall construction options.

Standard Framing

A very good cooler can be built using dimensional lumber and standard framing. Basic wall construction, sealing and insulating skills are needed to complete the work. Attention to detail regarding sealing and control of condensation and moisture migration is important. Moisture barriers should be considered on the inside of the cooler (high moisture load and occasional wash down) and a smooth cleanable finish surface should be installed as the last interior layer. A vapor barrier should be considered on the outside of the cooler walls to allow vapor migration out of the wall construction and to allow for drying of any condensation that may occur on the outside of the relatively cool surface on humid (high dew point) days.

A very good cooler can be built using dimensional lumber and standard framing. Basic wall construction, sealing and insulating skills are needed to complete the work. Attention to detail regarding sealing and control of condensation and moisture migration is important. Moisture barriers should be considered on the inside of the cooler (high moisture load and occasional wash down) and a smooth cleanable finish surface should be installed as the last interior layer. A vapor barrier should be considered on the outside of the cooler walls to allow vapor migration out of the wall construction and to allow for drying of any condensation that may occur on the outside of the relatively cool surface on humid (high dew point) days.

StoreItCold (www.storeitcold.com) the maker of the CoolBot refrigeration control system has a section of their site dedicated to cooler construction. Here they share the details of the wall section and recommended insulation options to use in a cooler and also provide an insulation guide. The Canadian Plan Service has some “tried and true” plans as well (see the 6000 series). Index: https://csbe-scgab.ca/images/cps/Plan-Index-EN.pdf, 600 series: https://csbe-scgab.ca/images/cps/E6000.zip

When using standard framing and staggered stud framing (below), take care to include rodent exclusion practices.

Also consider the details of the floor including drains, pitch, material and coving or curbing.

These are generally inexpensive additional steps that are easier to take during construction than later.

Staggered Stud or Double Wall Framing

“Advanced Framing” refers to alternate framing methods that still use standard dimension lumber, but achieve greater strength and/or higher energy efficiency in a wall section. One instance of this with relevance to cooler construction is something called a “staggered stud” or “double wall.” This method allows for deeper wall cavity using less framing material while also breaking the thermal bridge that standard framing with studs results in.

One of the better references on staggered stud construction is from the US Department of Energy – Pacific Northwest National Laboratory: https://basc.pnnl.gov/printpdf/1002}

The APA (Engineered Wood Association) Advanced Framing Guide is also a super reference with very in-depth guidance. https://www.apawood.org/data/sharedfiles/documents/m400.pdf }

Insulation Options for Wood Framing

- Mineral Wool batts – Good

- Cheapest, easy to install, fire and moisture resistant

- XPS Styrofoam (traditionally blue board, now grey) – Better

- Higher R value per inch vs. mineral wool, more difficult to install, can be sealed well using tape or canned spray foam to fill gaps

- Closed Cell Spray Foam – Best

- Typically professionally installed, has the best air seal once installed. Highest R-value material available

Vapor Barriers

There is often confusion about vapor and moisture barriers in wall construction. The intent of the barrier is to prevent condensation of moisture (water) out of the air from migrating into the wall. The balance of the wall construction is intended to allow for drying when that does happen. This is all in an effort to prevent the wall structure from being subject to molds, mildews and eventually rot. Most of the guidance about vapor barriers relates to residential and commercial construction where spaces are regularly occupied by people. A cooler is different since it is generally cold and humid when compared to the outside conditions.

Given the variation of temperature and humidity in the northeast throughout the year, it is possible to have condensation on both sides of the cooler wall at different times. For this reason, the use of solid, smooth, and cleanable wall materials with well-sealed seams and a vapor barrier underneath (between this finish surface and the insulation) is recommended on the interior of a cooler construction. The exterior surface should also include a vapor barrier, but the location will depend on the specific construction and provisions should be made for passive ventilation on the outside face of the vapor barrier. The prefabricated cooler panels above provide this inherently due to their design. A DIY framed construction should:

- minimize seams in sheathing,

- stagger insulation seams, and

- include careful attention to sealing with caulk/sealant in general.

An excellent and thorough review of vapor barriers is provided by Building Science Corporation which refers to US DOE Energy Climate Zones. This is focused on residential and commercial buildings, but the principles discussed apply generally.

Structural Insulated Panels (SIPs)

Structural Insulated Panels (SIPS) are well-insulated, prefabricated wall panels generally used in timber-frame construction to fill large sections of walls with a continuously skinned, well-sealed wall construction. These panels generally have plywood or chipboard as their outer layer, but can also be requested with smooth and cleanable surfaces more suitable to cooler construction. Some suppliers of SIPS in and near Vermont include:

- Foard Panel (West Chesterfield, NH) – http://www.foardpanel.com/

- Foam Laminates of Vermont (Starksboro) – https://www.foamlaminates.com/

- Tanguay Homes (Newport) – http://www.tanguayhomes.com/vt-structural-insulated-panels

- Mad River Post and Peam (Waitsfield, VT) – http://www.madriverpostandbeam.com/index.php

- Murus (Mansfield, PA) – http://www.murus.com/contact

- Real American Dream Homes (Bennington, VT) – https://www.realamericandreamhomes.com/

- Vermont Timber Works (North Springfield, VT) – http://www.vermonttimberworks.com/

- Wadworth Company & Vermont Barns (Bondville, VT) – https://www.sips.org/members/the-wadworth-company-vermont-barns

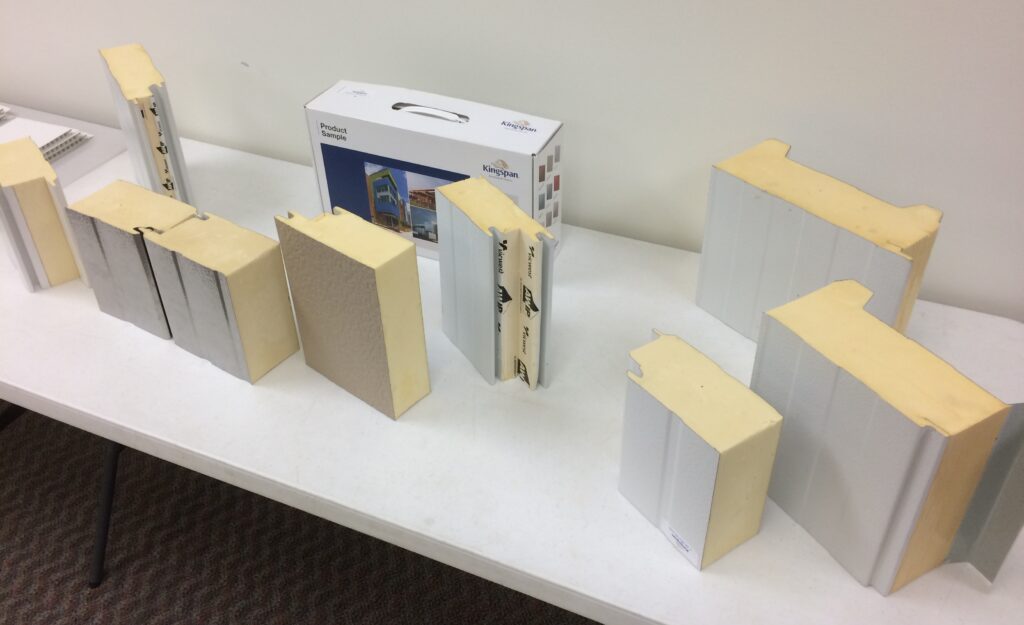

Metal Insulated Panels (MIPs)

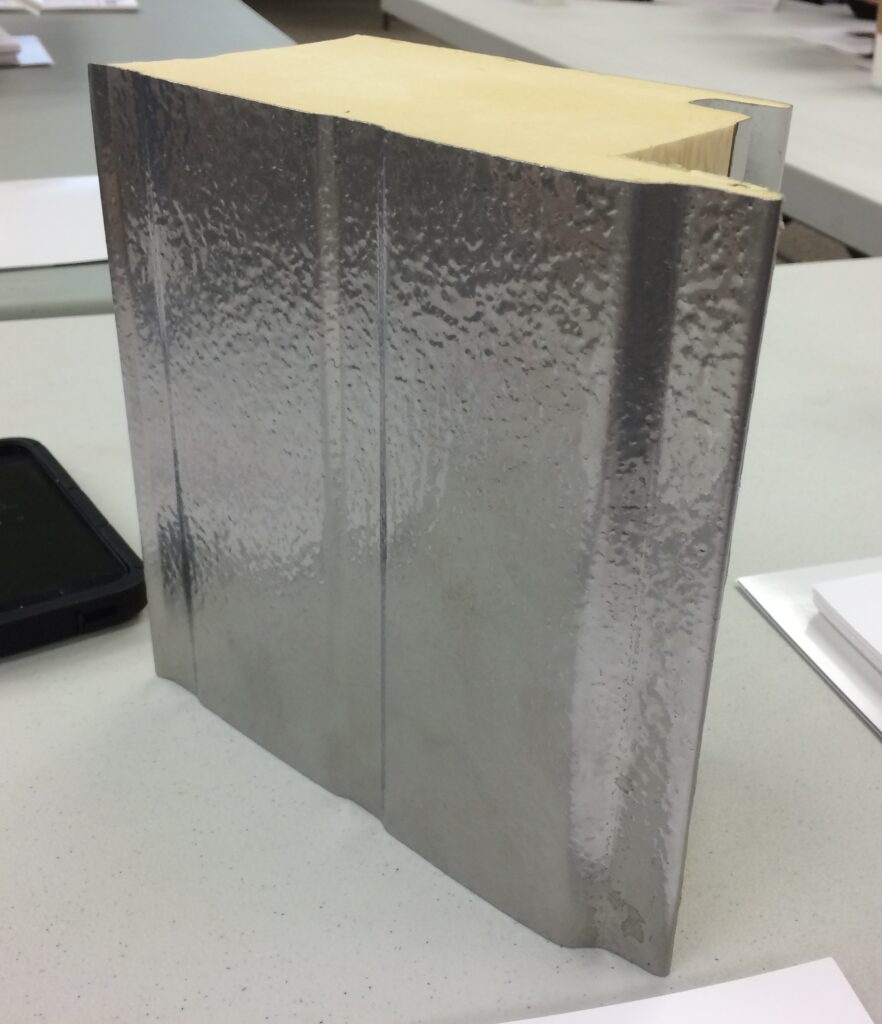

A variant of SIPs, Metal Insulated panels offer convenience as a cooler wall option. These are similar in construction to SIPs, but use thin metal skin in place of plywood.

A variant of SIPs, Metal Insulated panels offer convenience as a cooler wall option. These are similar in construction to SIPs, but use thin metal skin in place of plywood.

- King Span – www.kingspan.com

- Metl Span – www.metlspan.com

- PermaTherm – www.permatherm.net

Cooler Panels

Cooler Panels are modular panels conceptually similar to SIPS, but typically thinner with the outer layer being plastic, galvanized aluminum or another metal. These panels are designed to be standard sizes that click and lock together with cam-locks. Standard doors exist for these panels systems which allow for improved sealing without the need for constructing a customized door.

Suppliers of cooler panels include:

Suppliers of cooler panels include:

- American Cooler – www.americancooler.com

- American Wholesale Refrigeration (Cleveland, OH) – http://www.awrco.com/usedpanels.asp

- Akvatek – http://www.refrigeration-equipment.com/insulatedpanels.html

- Barr Refrigeration (Oshkosh, WI) – http://www.barrinc.com/insulated-panels/

- Bush Refrigeration (Camden, NJ) – https://www.bushrefrigeration.com/

- Therma-Loc (Perris, CA) – https://www.thermal-loc.net/thermal-loc-gallery-