By Chris Callahan, Hans Estrin, and Andy Chamberlin

Reading not your thing? We have a free, 8-Part webinar video series that goes into depth on all of the following topics discussed below.

Project Planning for Postharvest Efficiency, Profitability & Food Safety

Summary

Efficiency and food safety are integral parts of running a profitable and viable farm, producing high-quality produce, and retaining valuable employees. This integration should start with a vision in the planning stage of all postharvest projects.

Planning with efficiency and safety in mind ensures that growers “own” their systems and spend time and attention where it counts. This will help create systems and infrastructure that support business goals, markets, and production style. This ownership and planning are key to implementation success.

Focus areas of efficiency and food safety include flow, buildings, infrastructure, equipment, tools, and produce safety planning. Each of these topics will be explored below.

Flow

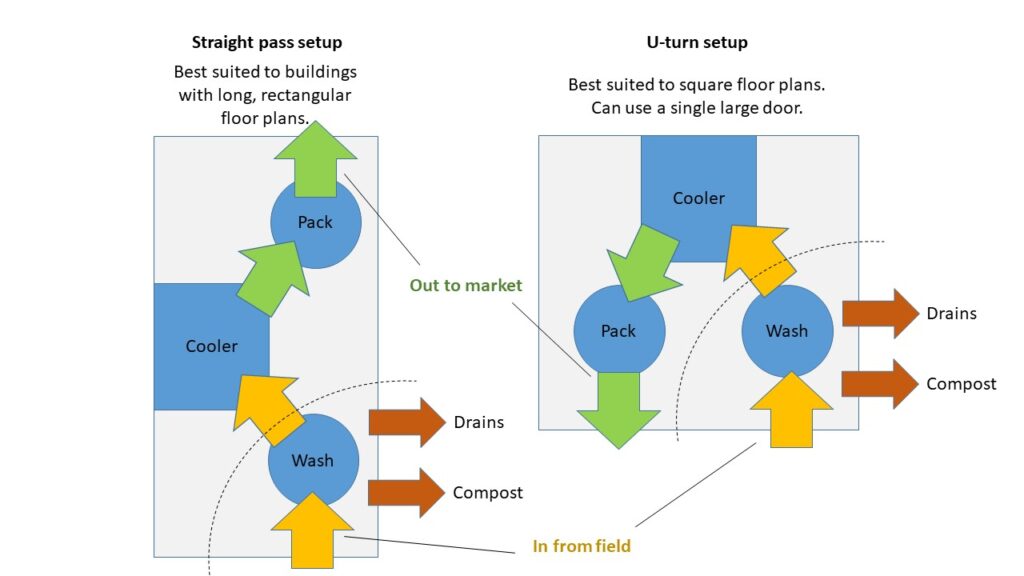

Following a key concept of “lean farming,” it is helpful to think about how things will move through your wash/pack area. We like to think about it in terms of how people, product, water, and waste flow through your space. Ideally, flow is in one direction to avoid backtracking (wasted steps) and potential cross contamination (clean produce intersecting that coming in from the field.) We have seen some creative solutions using U-flow to achieve the same goal in tighter quarters.

Flow of People

How do you and others move into and through the wash and pack area? If it is an enclosed building, do you have enough doors to allow efficient movement in and out of the space? Can you easily carry heavier totes of vegetables in and out? If you’re large enough to be moving vegetables with pallet bins, you may want a larger sliding or overhead door. If you are not in an enclosed space, you may still want to think about how foot traffic is prevented where you don’t want people entering or leaving the space.

Flow of Product

It can be helpful to zoom out and think about the flow of product from field to table or field to market. Looking at your farm using Google Maps can be helpful to think about locations of fields and wash/pack areas relative to each other. The routes between them also become clearer when zoomed out. Are you using the best route to move produce from the field to the wash/pack area? Are there any sources of contamination between the field and wash/pack like a compost pile or livestock area that should be avoided? Are you using the best bin, tote, or container for the produce and your operation?

Once produce is in the wash/pack it is usually best to work toward a directional flow from field to market in one direction. Avoid backtracking. Once produce is washed, keep it moving in the direction toward a cooler or market and avoid retracing steps with clean produce.

Establishing and maintaining a cold chain is important for preserving product quality. By reducing product temperature to appropriate storage temperature quickly, you reduce respiration and help maintain peak harvest quality.

Flow of Water

Water is typically used to wash vegetables, harvest bins, market bins, equipment, and tools. Do you have a reliable source of safe water? Have you considered hanging hoses to keep them off the ground? Once you are done with that water, where does it go? Intentional drainage helps keep water moving in the right direction (away from clean produce) and keeps the floor clear of standing water which can be a hazard. A good floor can also help with this. Similar to the way we want to avoid bringing clean produce back in the direction of the field, we also want draining wash water to head away from the place where we are using it to clean produce.

Flow of Waste

Washing and trimming produce can result in some residue that should be kept separate from produce for market. Seconds, culls, tops, etc. should be kept in a designated container and emptied in the compost pile, livestock feed trough or other “waste” stream daily. Compost piles should be located away from wash/pack areas. Accumulated produce waste can attract wildlife which can be a produce safety hazard.

Buildings & Infrastructure

You can wash produce just about anywhere, and we’ve seen some pretty creative, simple, and inexpensive setups. But, a little shade cover goes a long way and can be provided with a simple pop-up tent. A step up from that is a more permanent pole shed. Sometimes referred to as “four sticks and lid”, this can provide three seasons of comfortable space to work in.

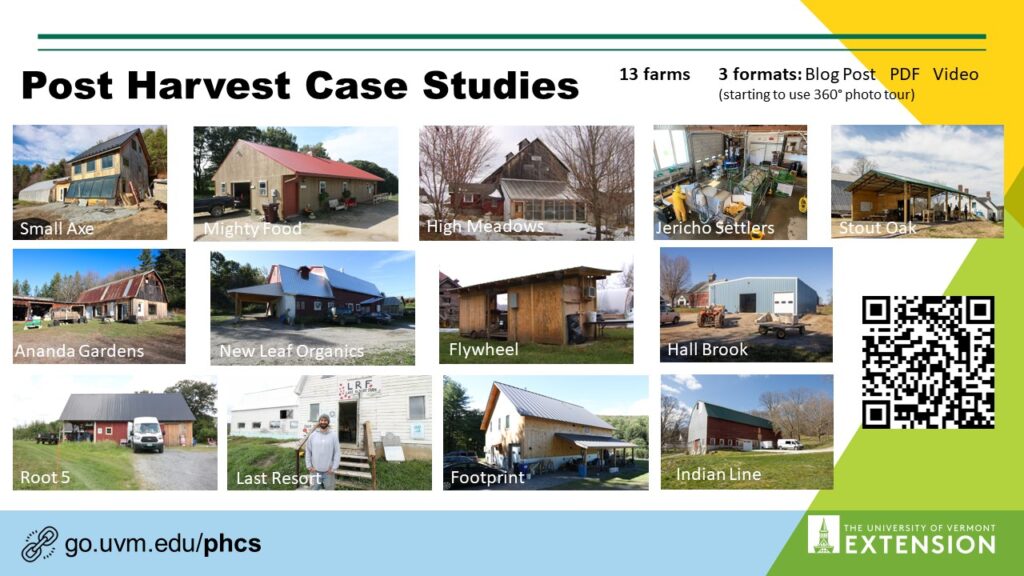

We’ve been compiling case studies that document individual grower decisions about wash/pack building, equipment and systems. You can find our growing list on our post harvest case study page.

If you’re planning on winter production or washing and packing winter storage crops, you’re probably going to want an enclosed space with a little heat. An insulated, heated space can be a life changer, although it does require an investment.

Once you are working in an enclosed space, you’ll want to think about lighting so you can work effectively.

Cold and warm storage spaces are also something most farms find useful. There are many options for building insulated walls that also keep rodents out. Many farms have found that using a CoolBot™ controlled air conditioner for cooling their spaces is a low-cost way of starting out with refrigeration. Some growers in northern climates have had good luck using an outside air exchange cooling system which brings cold, winter air in and exhausts warmer inside air using a thermostat controlled fan.

If you need to get a sense for the cooling or heating load of a storage room, you can use our online heating and cooling load calculator (we also have one for high tunnels and greenhouses). Freeze protection of cold storage and heating of warm rooms is also a common need which can be addressed with a small space heater on a thermostat.

Equipment

Washing equipment can be as simple as a sink or tub. Lots of greens growers make use of bubblers and greens spinners. Systems can also be more complex, taking the form of conveyor wash lines and root washing lines. Decisions about specific equipment will depend greatly on the scale of your farm operation, your market, your labor, and the crops you are handling and storing. We have started to compile a variety of case studies showing how farms of different scales and complexity have made their decisions.

It is important to make sure the equipment you are using to wash produce is washable itself. This is known as hygienic design, and we have some resources that can help you apply this principle to your farm.

Tools

There are a wide variety of tools that can make the washing and packing of produce easier and more efficient. We’ve mentioned the wide array of bins, totes, and containers that are available. Using different containers (or different colors) for harvest, storage, and market can help improve handling and safety.

Tools should be easily cleaned and sanitized for the same reasons as equipment. Having a dedicated place for storing tools when not in use can help keep things clean and organized. A magnetic knife strip, for example, is a common favorite. Hose reels are also a very popular tool for keeping hoses handy, but out of the way when not in use.

For more information about cleaning and sanitizing, including a summary of cleaning tools check out our SCRUB Project Page.

Budget

We recently polled the Vermont Vegetable and Berry Growers Association members to see what recent wash-pack projects had cost. Below is a summary of wash-pack and cooler costs as of 2022.

- Wash/Pack

- 4 Season, enclosed, insulated, metal building: $70-80 / sq ft

- 4 Season, enclosed, insulated with living space above: $80-90 / sq ft

- 4 Season, enclosed, insulated, wooden framing : $37-60 / sq ft

- 4 Season, renovated dairy barn: $21-36 / sq ft

- 3 Season, prefabricated shed: $45-50 / sq ft

- 3 Season, wooden framed shed or pole barn on slab: $21-50 / sq ft

- 3 Season, shipping container: $15-17 / sq ft

- 3 Season, wooden framed shed on PT base with plywood flooring: $14-16 / sq ft

- Pop-up tent: $1 / sq ft or less

- Coolers

- Modular Panels, with equipment: $250 / sq ft, $13 / cu ft

- Wooden framed, spray foamed: $167 / sq ft, $8 / cu ft

- StoreItCold, complete, delivered: $172 / sq ft, $22 / cu ft

Food Safety Plans and Certification

To maximize the benefits of implementing produce safety practices, growers should examine every step of their production system with an eye toward managing and minimizing food safety risks. This effort will also reinforce focus on efficient flow of products, people and materials, durable, cleanable food contact services (hygienic design), and dedicated systems, bins, and tools. Food safety planning also focuses on employees; in building a culture of good personal hygiene, risk management thinking, and systems thinking. This planning also results in clear Standard Operating Procedures (SOPs) for postharvest handling, storage, and clean-up. This clarity can provide ownership and creative management opportunities for employees, and can increase crew morale, productivity, and loyalty.

Based on markets and gross revenue, farms may need to verify the implementation of food safety practices by earning a certificate, completing a third-party audit and perhaps even being inspected by state regulatory authorities. A limited number of state and national programs provide food safety templates, certificate programs and audits for Vermont produce growers (e.g. VT-CAPS), allowing them to access markets, and build market integrity.

Some larger Vermont farms may also need to be inspected by state regulators and required to comply with The Food Safety Modernization Act (FSMA) Produce Safety Rule.

Regardless of your specific need, starting with a vision of efficiency and safety and walking through each step of your postharvest handling, storage and distribution system will help clarify and prioritize areas for improvement and growth.

Design Your Own!

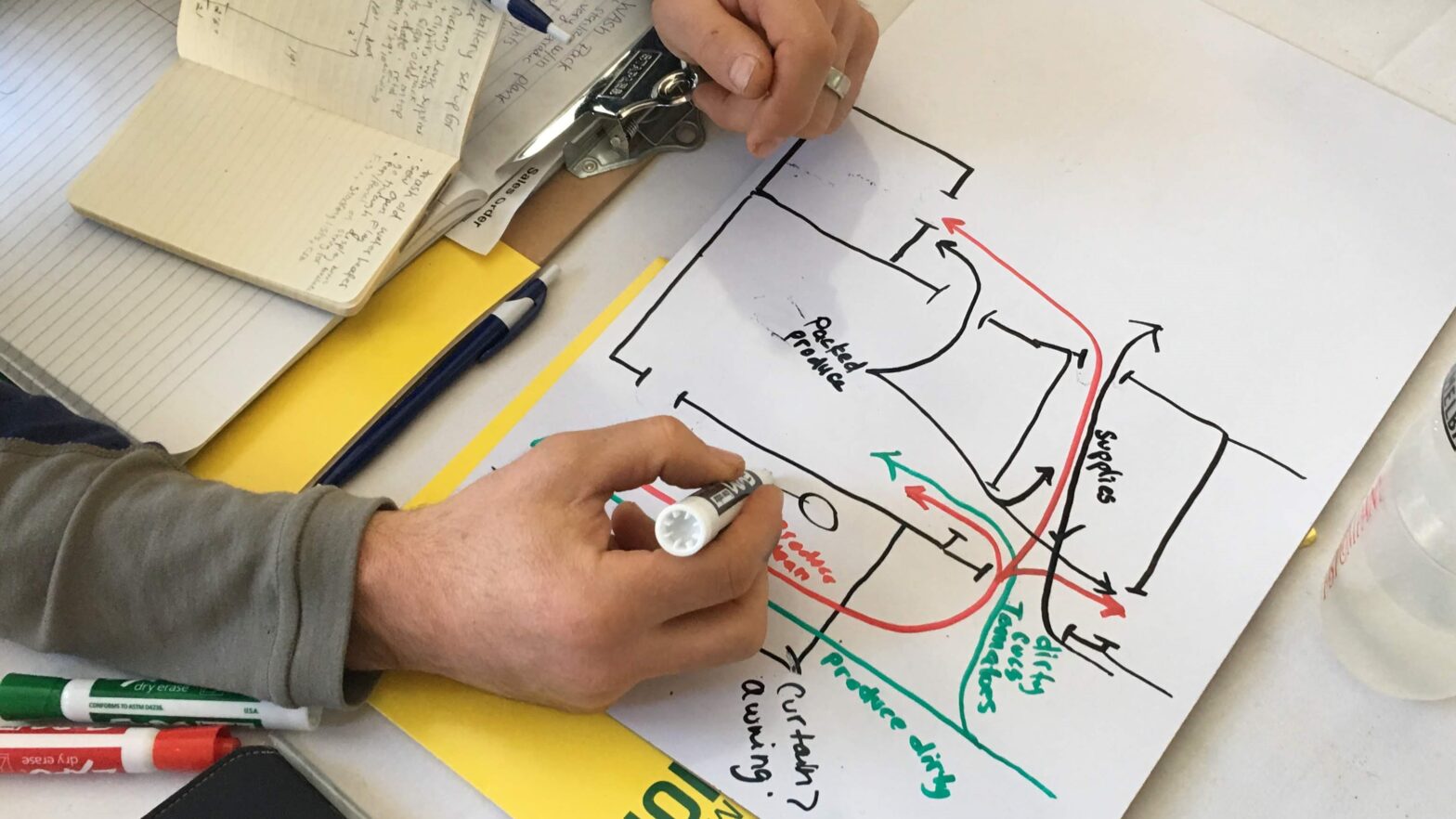

We have found use of PowerPoint to be simple enough, and user friendly to use to layout floor plans to scale. Though graph paper and cutting out shapes works for many, doing digital sketches is helpful for others.

Here is the template we use, and examples from other projects you can reference.

Looking for more content? Explore additional postharvest resources here.

Share this blog post with others!

About Us – Chris, Hans, and Andy are the UVM Extension Produce Safety Team. They work with growers to improve efficiency, quality, and safety of produce farms. This guest blog post is a summary of a half-day postharvest planning workshop they hold through-0ut the year. They can be reached at producesafety@uvm.edu. Learn more about the work Chris and Andy do with the UVM Extension Agricultural Engineering program at http://go.uvm.edu/ageng and follow them on social media at @uvmextageng. Learn more about Hans’ work with the VVBGA Community Accreditation for Produce Safety, CAPS) at https://practicalproducesafetyvt.wordpress.com/.