This guide provides background on planning for drains and drainage from produce wash and pack areas. Direct drains, floor and spot drains, and trench and gutter drains are discussed. A construction drawing for a trench drain is also provided.

Tag Archives: Pack

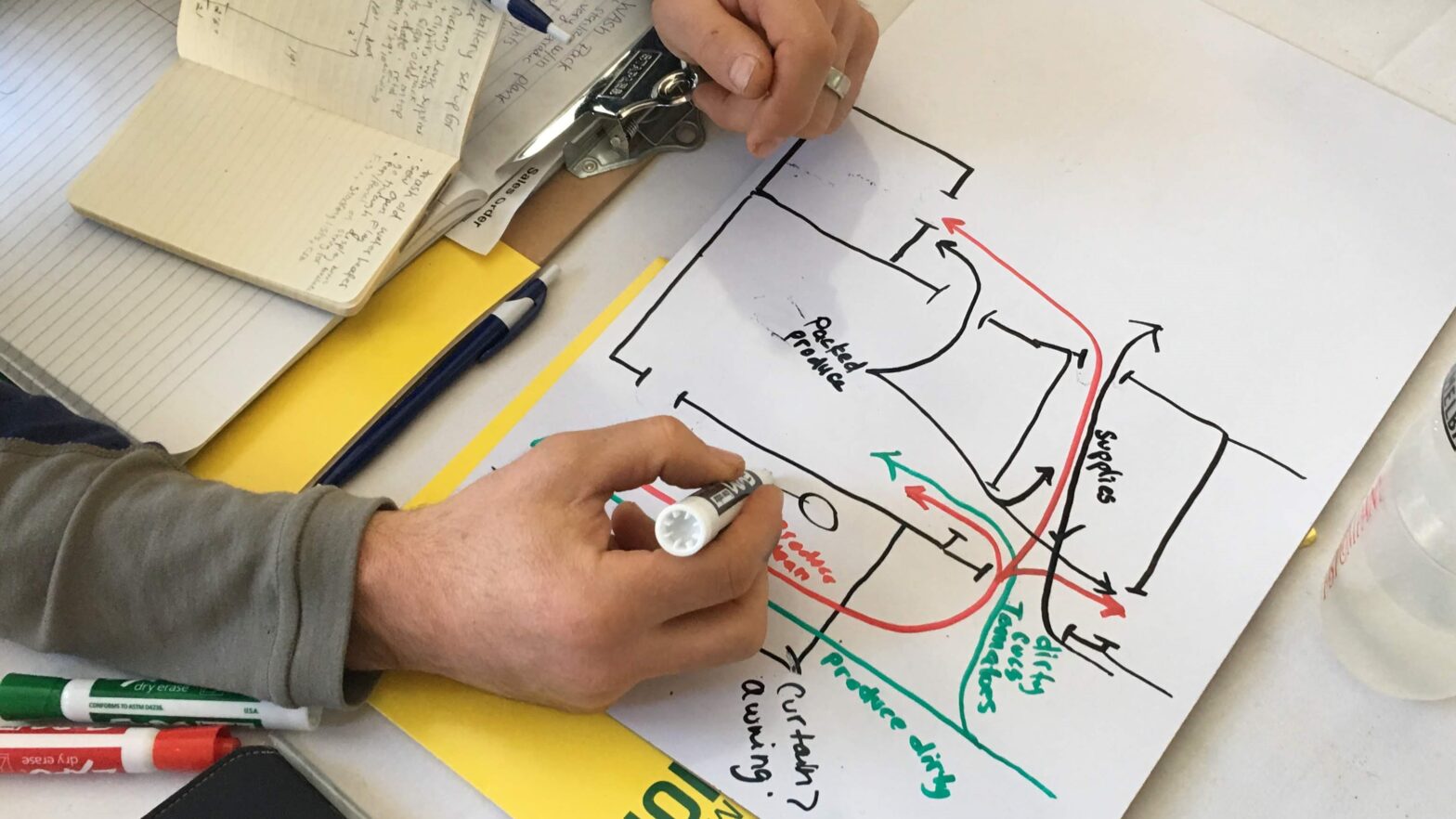

Planning an Efficient and Safe Wash/Pack Area

By Chris Callahan, Hans Estrin, and Andy Chamberlin Reading not your thing? We have a free, 8-Part webinar video series that goes into depth on all of the following topics discussed below. Project Planning for Postharvest Efficiency, Profitability & Food Safety Summary Efficiency and food safety are integral parts of running a profitable and viable …

Continue reading “Planning an Efficient and Safe Wash/Pack Area”

Mighty Clean and Comfortable (Video Series)

Lisa MacDougall has led Mighty Food Farm through start-up, relocation from rented land to owned land, and now through the construction of a brand-new 60 ft x 90 ft wash and pack shed. She’s done this all while producing a diverse mix of organic vegetables, tree fruit and berries on fourteen acres, now, in Shaftsbury. …

Continue reading “Mighty Clean and Comfortable (Video Series)”

The BarnHouse: Optimized for Modern Day Vegetable Farming at Footprint Farm

Download the PDF Fact Sheet of this Post Harvest Case Study Here! Taylor and Jake Mendel own and operate Footprint Farm in Starksboro, VT. Starting their own farm in 2013, they now produce pretty much everything except storage potatoes and storage squash with 66 different kinds of vegetables grown in both fields and high-tunnels. About …

Continue reading “The BarnHouse: Optimized for Modern Day Vegetable Farming at Footprint Farm”

Postharvest Resource Survey

We are seeking input regarding a research and education project with the goal of consolidating postharvest information in a single set of resources. Our proposed project aims to consolidate existing knowledge, best practices, and new developments in postharvest equipment, infrastructure, and buildings into a web-based handbook, workshop curriculum / educational materials and recorded videos. Click …

Floor Design for Vegetable Wash, Pack and Storage Areas

Download the PDF Fact Sheet Here! Introduction It is easy to ignore the thing beneath our feet, but floors are an important part of produce wash and pack areas that deserve special attention. They can impact efficiency, ergonomics, employee health, worker fatigue, personnel safety, and produce safety. There are also a number of design features …

Continue reading “Floor Design for Vegetable Wash, Pack and Storage Areas”