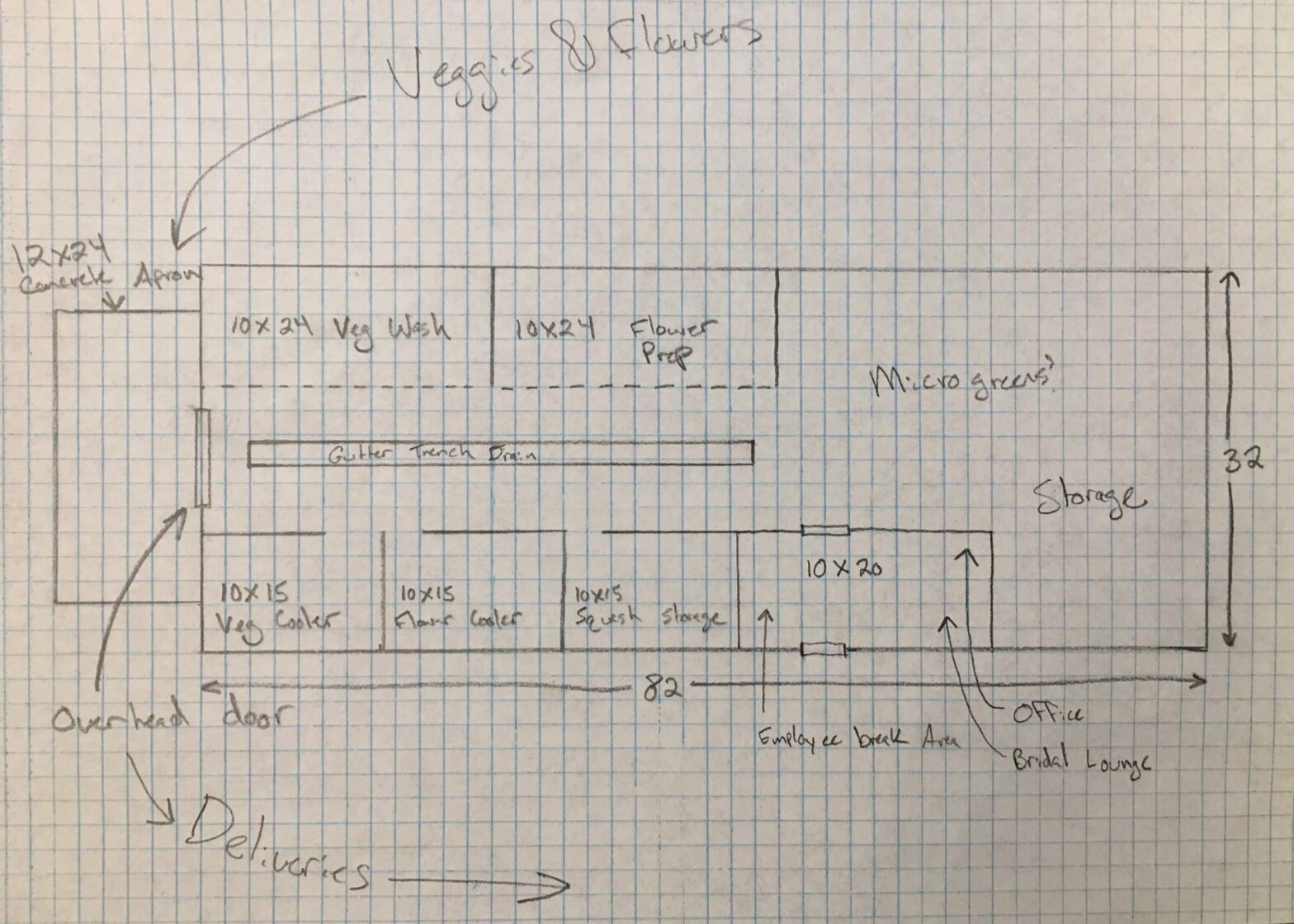

Lissa Goldstein runs the farming operation at Wild Work Farm in Keene Valley, New York nestled in the Adirondack Mountains. Wild Work is a diversified vegetable farm with some blueberries and fruit trees. When Lissa heard we were building out examples of wash/pack areas she reached out to share details of her shipping container project, …

Continue reading “Planning Tames the Postharvest Beast at Wild Work Farm”