Sanitizers used for treating post-harvest agricultural water on produce farms often come in 2.5, 5, or 10 gallon totes. These totes can be cumbersome to pour from resulting in splashing and spilling. These chemicals are also shipped in concentrations that can cause injury.

Here are some simple ways of increasing the safety and accuracy of sanitizer dispensing.

Click here to view a PDF Version of this post.

Safety First

Remember that you are dealing with chemicals that can hurt you and your crew. Check the label and material safety data sheet (MSDS) for the product you are using and be sure to follow proper handling procedures and use proper personal protective equipment (PPE). Appropriate PPE is typically a minimum of rubber gloves and safety glasses or goggles, but you may want to consider an apron and long sleeves. Also be sure you are working in a well-ventilated space.

Keep in mind that most sanitizers off-gas to some degree. When stored in their shipping containers and even in spray bottles or dispensing bottles, it is important to slowly vent the contents occasionally to prevent bursting the container and having a leak and spill. If you aren’t using the product regularly or if it is particularly hot outside, watch for bulging containers and take care to slowly open the cap to vent and reduce the pressure slowly.

Also remember that any time you dispense from the shipping container into a new (secondary) container, the secondary container should be clearly labeled to prevent misuse or injury. See below.

Use Standardized Dosing Measures

If you are regularly adding sanitizer to specific dunk tanks or sinks and know the volume of them, write down the correct dose of sanitizer once you calculate it. Make this part of a brief standard operating procedure (SOP) that anyone on your crew can follow once they know what is being washed and in what container.

Taking this a step further, consider getting a measuring scoop or cup that is used just for this purpose. Mark it with permanent marker or in some other permanent way at the level corresponding to specific amounts used regularly on your farm. You can also trim the scoop to measure just the right amount. If you have lots of different uses, consider using multiple measuring cups and label them or maybe even color code them according to their specific use.

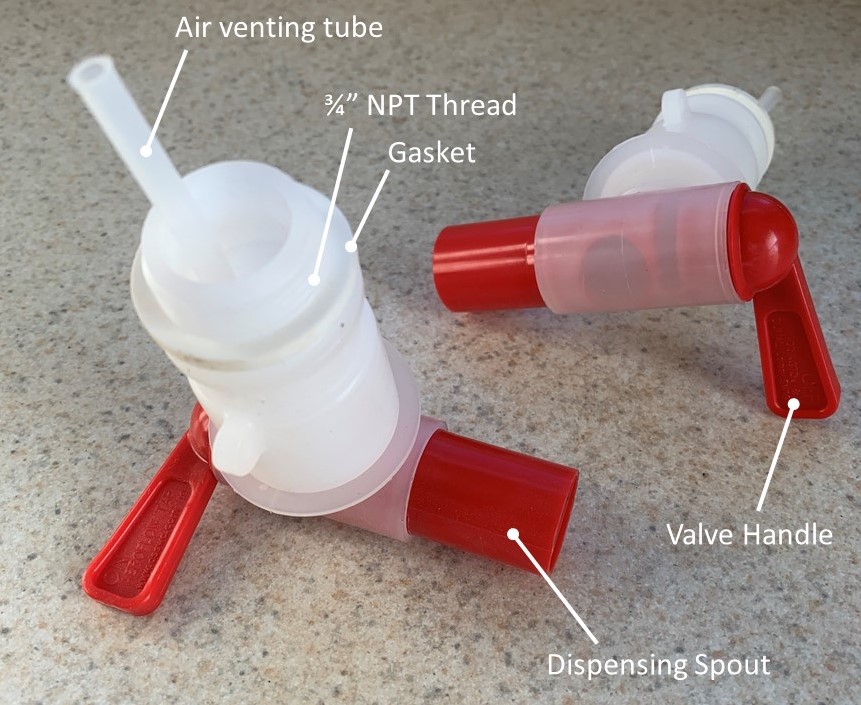

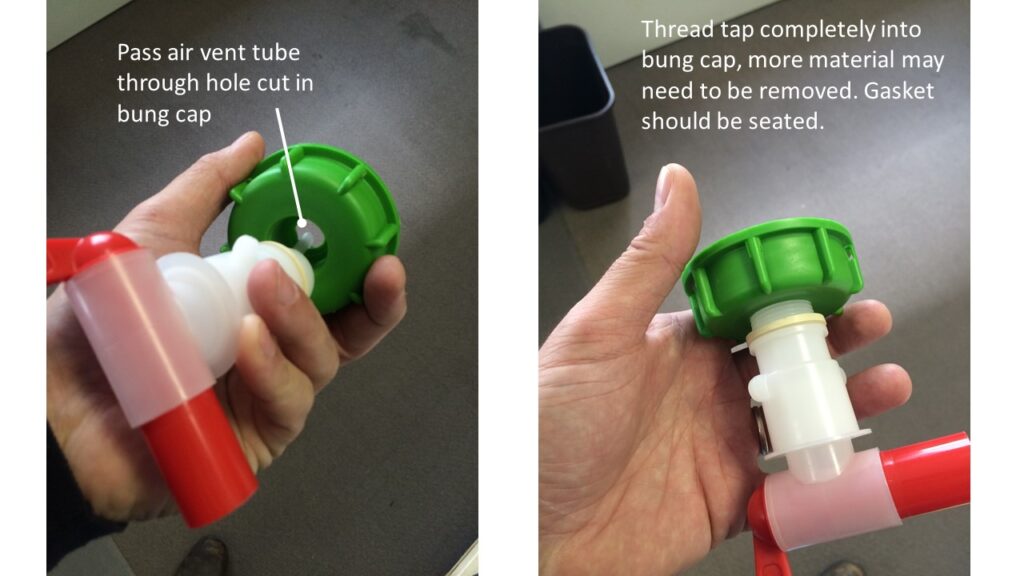

Install a Spigot on the Tote

The single easiest thing to do to improve your dispensing of sanitizers is to install a spigot (also called a “quarter-turn valve” or a “self venting tap”) on the tote. The totes come with a bung cap that has a threaded insert typically with 3/4″ FNPT thread. A spigot or quarter-turn valve can be threaded into that bung cap to allow for a simple way of dispensing the chemical without having to lift and pour from the tote. You will need to drill a hole in the solid base of the bung cap where the threaded inset ends to allow the air tube from the spigot through and to allow fluid out.

Aeroflow 3/4″ Self Venting Tap from US Plastics – $3

Use a Twin Neck Bottle

You may have seen two-stroke oil sold in a twin-neck bottle (also called a “double-neck” or “tip and pour” bottle). These bottles are designed to allow you to measure the right amount of fluid form a larger reservoir and then dispense only the measured amount. It is a great tool for lots of farm applications. In this case, you could fill the larger reservoir with a week’s worth of sanitizer from a tote with a spigot (see above) and then measure and dispense safely, quickly, and easily.

Twin Neck Bottles from US Plastic – 8, 16, and 32 oz. – $1-3

Twin Neck Bottles from The Cary Company – 8 oz to 2 liter – $1-4

Secondary Container Labeling

When you dispense sanitizer from the shipping container into a secondary container for ease of use, be sure to label the secondary container clearly. Avery has two labels for this purpose.

2″x4″ labels for secondary containers

3.5″x5″ Labels for secondary containers

Use a Pipette for Smaller Volumes

If you are mixing up a spray bottle or other small volume of sanitizer solution, a smaller dosing measure may be needed. For example, to mix a 32 oz spray bottle with a Sanidate 5.0 solution used for sanitizing hard food contact surfaces, you’ll want to add about 9 mL (a little more than 1/2 Tbsp) to the spray bottle and fill with 32 oz of water. A pipette is a good tool for this job. These are something like a mini-Turkey baster or eye dropper and are available in a range of sizes with graduations to allow measuring. Calculate the needed dose to determine an appropriate size for your needs. A good practice when using pipettes is to pickup more solution than needed and then squeeze the extra out back into the container to achieve the desired dose amount. One piece plastic syphons are recommended over pipettes which are loaded by inhaling with your mouth.

One Piece Syphon Pipette US Plastic – 5, 7.5, 8, and 15 mL – 100 pcs – $0.30 – $0.40 each.

10 mL Plastic Pipettes on Amazon – 20 pcs $11, $0.58 each

How Much Should I Use?

The amount of sanitizer you use depends on the intended purpose. For a review of how the dose varies with use, read A Guide to Cleaning, Sanitizing, and Disinfecting for Produce Farms.

Example: Sanidate 5.0 is intended to be used at a concentration of 27-96 ppm according to the label when used for postharvest wash water treatment. This means a “dose” of 0.06-0.20 fl. oz. of Sanidate 5.0 per gallon of wash water. For leafy greens, Biosafe, the manufacturer of Sanidate, recommends 40-60 ppm which means 0.10-0.14 fl. oz (roughly 1/2 to 1.0 teaspoons) per gallon of water. Dosing at the high end of this range will provide extra sanitizer which is helpful since it gets used up during the wash cycle. You should confirm the concentration of sanitizer at the start and end of the wash cycle using test strips. Our online dose calculator may be helpful.

Manual Pumps

A manual plunger pump (also called a “pail pump” or a “drum pump”) can be attached to a tote in place of the bung cap. These are similar to what you may have used for dispensing ketchup or mustard at a condiment station in a restaurant. As you push down on the spout plunger, fluid is forced out through the spout. These make it easier to dispense the fluid without lifting and pouring from the tote, but require some coordination and don’t provide direct measurement.

Pail/Drum Pump from ULINE, $14

EZI Pail Pump for 5 Gallon Container – $100

Goat Throat – $392 – GoatThroat 300 Pump with Viton seals. (NOTE: As of early 2020, an adapter is needed to attach this pump to Sanidate 5.0, 5 gallon carboys.)

Flow Driven Injectors

A flow driven injector may be an efficient option for farms that use large tanks or frequently change water. These injectors are installed in-line with the water fill line (though typically have bypass circuits as well). As the water flows through the injector, it drives a pump inside that brings in a specific, but adjustable, ratio of chemical.

Dosatron options – D14MZ2 – $940-1000.

Cleaning and Sanitizing Videos

There are 4 videos in this playlist that highlight how to clean, use, and handle detergents and sanitizers.

Share this post!

Use this short link to share this blog with others: http://go.uvm.edu/sanitizerdispensers

Acknowledgements

This resource was developed as part of the Food Safety Outreach Program under grant number 2020-70020-33003 from the USDA National Institute of Food and Agriculture and also funded, in part, by the USDA Northeast Sustainable Agriculture Research and Education program through award LNE19-375 and by the Food and Drug Administration through The Vermont Agency of Agriculture Food and Markets via the Integrated Extension Educational Programming in Support of the VAAFM Produce Program Grant 02200-FSMA-2018-01. The views expressed in the publication do not necessarily reflect the official policies of the U.S. Department of Agriculture, the U.S. Department of Health and Human Services or the Vermont Agency of Agriculture; nor does any mention of trade names, commercial practices, or organization imply endorsement by the United States Government or the State of Vermont. It is offered without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, disability, protected veteran status, or any other category legally protected by federal or state law.

This project was supported by the Food and Drug Administration (FDA) of the U.S. Department of Health and Human Services (HHS) as part of a financial assistance award 02200-FSMA-24-01 totaling $30,000 with 100 percent funded by FDA/HHS. The contents are those of the author(s) and do not necessarily represent the official views of, nor an endorsement, by FDA/HHS, or the U.S. Government.