This blog post is for those using or considering a converted washing machine as greens spinner.

Background

For background information on several different types of greens spinners and general thoughts on using washing machine conversions see this blog post.

If you’ve purchased a machine and are ready to convert it, see our Washing Machine/Greens Spinner Conversion Guide

Shopping Tips

There are a few things to consider when shopping for a washing machine to convert into a greens spinner. Like most things, it comes down to:

- How much you want to spend, and

- What features are important to you.

Option 1 – A Basic Machine

There are few things you need to look for in searching or a washing machine that will be used as a greens spinner. A good rule of thumb is: The simpler the better. Fancy electronic controls are not used for this application; you only use the spin cycle. The pictures below show a Whirlpool WTW5000DW model which was used for our first review. Most models on the market are put together in similar ways, but individual washers will vary. This washer and others like it can easily be purchased at box stores. You can expect to pay $600-900 for these basic models. Other models are available from different manufacturers but they have not been evaluated by us yet.

Key Points

Top-loading washers are needed for greens spinning. Front-loading washers pose challenges in both use and cleaning.

Washers with an “impeller” or wash plate rather than an “agitator” up the middle allow easy use with basket inserts and require less modification.

Some washing machines have an agitator that can be removed, providing enough clearance above the drive shaft for using a basket insert. We’ve observed that machines with a stainless drum with an agitator are easily removed but those with ceramic/painted drums have driveshafts that stick-up too far which prohibits the use of a basket.

Start with a new clean washer. It is tempting to use the free, used washing machine you found on the roadside. But, remember, you are washing salad that people put in their mouth, so these machines need to be kept extremely clean. Because of this, we also recommend using a basket insert to spin your greens over directly placing them in the drum, or using a laundry bag. This makes the basket (which is easier to keep clean) the primary food contact surface and not the components of the spinner.

Whether you’re starting with a new washer or performing maintenance on your existing one, this next tip will ensure you are minimizing harborage points for bacteria and foodborne pathogens.

Avoid 3 Phase Motors!

Many brands are coming out with “direct drive” (no belt), “quiet” or “efficient” machines. Use caution as these variable speed motors can not be wired for this intended purpose.

Downsides of “Basic” machines

Hard to Clean – Areas between the sidewalls and the drum are hard to access for cleaning.

Visually Unappealing – Washing machines are not visually appealing, especially when they’ve been hacked for farm use. Technically speaking they can be cleaned and maintained (read more tips below) to reduce produce safety risks. However, they can raise a flag for an auditor or inspector.

Drum Modification Required – Baskets don’t fit securely in the drum, and additional “bumpers” need to be installed for use.

Can Be Noisy – Loads can get out of balance, especially when modifying the drum to fit baskets. This causes the machine to wobble and shake. Sometimes the drum will even slap the sides of the machine. This makes for a very loud workspace and excess wear on your machine.

Sharp Edges – A hacked top or the edges of side panels can be sharp. The temptation to cover these with a split hose reduces the risk of cuts but increases harborage risk and creates additional pathogen growth locations.

Option 2 – A Commercial Machine

The second option we have explored is a high end washing machine. These machines are made for the commercial market and are generally benefit from a more robust design. They really are the “cat’s meow” when it comes to washer conversions. They come with a price premium, but it is likely well worth it considering the benefits. The model we reviewed is the Speed Queen TC5. These are not found in the typical box stores but, rather, in appliance stores. These machines are in the $1,200-1,500 price range. Other commercial washer models from various manufacturers like Whirlpool etc. are available, but their build and features have not been evaluated by us yet.

Beneficial Features

There are several benefits that the higher end washer gains you that we think is worth the extra cost. Everything from the ease of modification, quality of the machine components, hygienic design of the final build and daily ease of use.

Ease of Modification – These washers are designed and built with clear attention to detail. Parts are designed to be easily removed or replaced and not designed cheaply as a use-and-replace appliance.

Low Attachment Point Agitator – This brand of washer DOES have an agitator up the center, however the way it connects to the drive shaft is low enough in the drum so it doesn’t interfere with using a basket insert.

Direct Fit Baskets – The drum is the right diameter to fit orange harvest baskets without bumpers or spacers to secure the load.

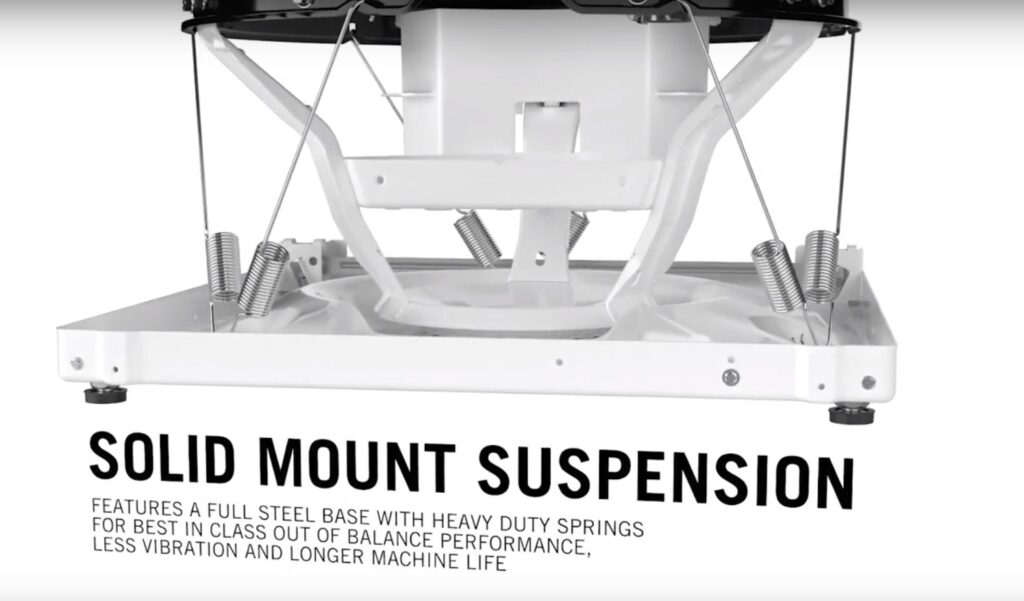

Quieter Operation – This machine has a bottom-mounted design (supported from a base on the floor) rather than chassis mounted (hung from the side panels). This keeps the load in better balance reducing excess vibration, noise and stress on the components. It also allows the top to be more open and reduces sharp edges and harborage points.

Improved Electronics – The wiring harness uses a higher gauge wire and is easy to dissemble to wire to a timer switch.

Single Piece Drum – The drum on the speed queen’s is fully stainless steel and has smooth drains holes and does not include stamped, molded or sandwiched pieces of plastic. These extra pieces and design features on the Basic Model create seams and sharp edges that are hard to clean and sharp to handle.

Automatic Drum Brake – This machine is equipped with a mechanical brake that automatically stops the drum from spinning at the end of the cycle. This reduces the time it takes for the basket to slow down and stop. Basic machines coast to a stop and users find themselves waiting, or using their hands to stop the drum early.

Compact Design – Since the unit is bottom-mounted, the sides of the machine are not needed, and can be removed. This makes the unit lighter and take up less space in your wash-pack area. This makes it a more enjoyable place to work providing more open space and less visual clutter. (+1 for not looking like a misplaced washing machine, or Frankenstein appliance anymore!)

Easier to Clean – Removing the sides also increases the ability for the machine to fully dry between uses. This reduces conditions that favor growth of bacteria and other pathogens.

Early findings on the Commercial Washer Model

We have our first version running at a partner farm (Footprint farm) for a long term use test. Early reports suggest that it’s a great washing machine spinner. We increased the size of the drain holes in the bottom of the drum to make the daily cleaning (hosing out small leaf material) quicker and easier. Taylor and the crew repeatedly comment about how nice and quiet the machine operates. Yay for hearing the radio, and other crew members as you pack for customers!

We tried installing it on casters, but found that to not hold very still, so we put it back on it’s feet and bolted a hand truck to it. So far this is working well!

NOTE: The Speed Queen model TC and TR Models are significantly different: The TR models do not have the brake and has a 3-phase motor that can not be wired for this intended use.

Not sure if a washer spinner is right for you? Learn about other options

Looking for best practices and how-to info on cleaning and maintenance? Check out these videos.

PDF procedures to convert a washing machine to a greens spinner are available here: Washing Machine/Greens Spinner Conversion Guide