Compiled from VVBGA farmer input by Becky Maden, Chris Callahan, Vern Grubinger, and Andy Chamberlin.

Introduction

High tunnels and greenhouses provide protection for crops, extend the growing season, and improve yield and quality. However, climate change brings both a higher frequency and increased intensity of extreme weather events. It is important to think about how high tunnel structures can best be built and modified to endure the extremes. The information below is a summary of experiences shared by the growers of the Vermont Vegetable and Berry Growers Association (VVBGA). Individual grower comments and references for more information are provided following the summary.

Download a PDF of this post here.

Contents

(Click below to jump to a section, or scroll on…)

Before You Build

Siting

Invest in site selection and development before construction begins. Avoid wet or flood prone areas. Build a raised pad for the tunnel that elevates it from surrounding land. This allows for drainage of rain in warm weather and snow melt in colder weather when the ground may be frozen.

Before driving in ground posts, install drainage, leaving 18-24″ of space between a French drain and ground posts. Make sure there is a place for the water to drain to that is not an adjacent field or tunnel. Remember that tunnels shed a lot of water in rainstorms. That water needs somewhere to go quickly.

Leave room for snow clearing between and around tunnels. Consider both the room needed for snow clearing equipment and also where the snow will go.

Consider prevailing winds and air movement. Site tunnel where there will be good cross ventilation, but not high winds. Plant windbreaks if necessary.

Design

Structure

When purchasing a tunnel, choose as much structural reinforcement as possible to support snow loads and high winds. Be sure to account for primary crop load (tomatoes, hanging baskets, etc.) This may include the size of structural pipes, number of trusses and truss bracing, wind / corner bracing, and strong purlin to bow connections (cross braces and through-bolting vs. strapping.)

Build strong end-walls and make sure they are anchored to the ground to prevent uplift (the upward force that can occur in high wind events). End walls are often the weak point in the design and once they lift or otherwise fail, wind will wreak havoc on the rest of the structure.

A steeper roof pitch (6:12 or 26.6°) can promote snow shedding. Even one degree less can make a difference. The gothic shape is designed to shed snow.

Ventilation

Ventilation fans can push hot air out and draw in cooler and/or less humid air. These systems should be designed well to ensure that they are actively drawing air through the tunnel.

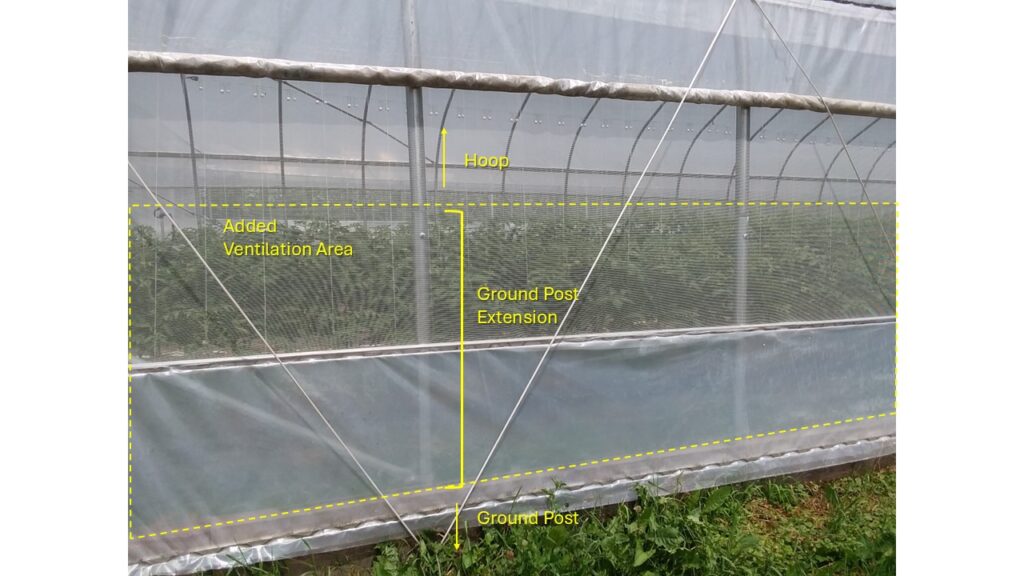

If relying on passive ventilation, install large openings for maximum airflow. This starts with high sides for roll up or roll down systems, which may require adding extended ground posts.

End walls should have large openings (doors, gable vents).

Ridge vents will optimize passive air flow because heat rises.

Be careful to avoid mixing passive and mechanical ventilation at the same time. An exhaust fan running with the sides rolled up will pull air from the path of least resistance (the closest opening of the roll-up side), and may provide little benefit.

For lower cost tunnels without automation, gable end or butterfly vents are a good option to improve passive ventilation. These can be easily installed after construction. Consider multiple vents or larger single vents.

Controls

Consider investing in automated systems and controls that may respond to changes in temperature, increased wind, and even precipitation more quickly than you can.

Strategies for Existing Structures

Structural Maintenance

Check plastic before anticipated storms. Patch holes, secure wiggle wire, tighten loose areas to reduce flapping .

Check structure seasonally and tighten any loose brackets, replace rotting lumber on endwalls, hipboards, and baseboards. Plumb endwalls as needed.

Rain and Flooding

For tunnels already built, install drainage, swales, or other water diversions to steer water away from tunnels. Avoid excavation within 18-24” of ground posts which can reduce their resistance to uplift.

Build raised beds and use mulched pathways inside tunnels. Adding organic matter to tunnel soils can improve the “sponging” capacity of the soil and water infiltration. In tunnel walkways, wood chips can help absorb water and reduce compaction.

Wind

Shut all the doors and keep the wind out. This may mean extra latches on doors, bracing doors with cinder blocks and rebar, tying down roll-up sides, securing louvers and ridge vents, etc.

Patch all plastic tears and check wiggle wire fastening.

Add extra trusses and bracing. Some growers have trusses added to every bow and invest in additional wind or corner bracing.

Strapping over bows that attach at the ground posts can help prevent uplift in high winds.

Snow

Double layer, inflated plastic helps shed snow.

Consider temporary bracing with 2×4 posts under hoops especially in Quonset hut style tunnels or those with weaker hoops.

Clear snow evenly from both sides, a little bit at a time, to prevent eccentric loading on the bows (takes longer, but may prevent damage).

Heat the house to melt snow as it falls. Heating the house, even minimally, can prevent accumulation of snow and minimize snow clearing needed.

Gear up! Consider getting a snow shovel with an extra-long handle, a wide long handled broom with soft bristles, and a good pair of snowshoes.

Heat

Use shade to keep crops cool. Use 30% shade cloth. Research shows that white shade cloth allows more plant available light through but for short durations, black is effective too.

Coating the exterior of the tunnel with a washable material provides temporary cooling. Surround WP, lime, or Koolray are recommended.

Lighter colored mulches help cool the soil such as straw, white landscape fabric or white plastic. Mulches can also help keep soil evenly moist during hot periods.

Moving air through the tunnel helps plants stay cool. Passive ventilation such as roll up sides, butterfly vents, and doors should be fully open during hot stretches. See above for design guidance.

Taller ground posts (extra roll-up side area) can improve passive ventilation flow rate. This also provides more flow area to compensate for restricted air flow due to any insect netting.

Ventilation fans can push hot air out and draw in cooler and/or less humid air. See above for design guidance.

Circulation fans such as horizontal air flow fans (HAF) or vertical air flow fans (VAF) move air through crops which helps keep plants cool, reduces humidity, and disease, and can increase pollination during hot humid stretches. See above for design guidance.

To reduce plant stress during hot periods, be sure to keep plants well-watered; do so during cooler times of the day. Check the soil regularly to make sure it is moist.

Adjust horticultural practices. For crops that are prone to sunscald or sunburn, do not prune the leaves or suckers directly above fruit and expose it to direct sunlight. Reduce pruning stress during hot periods.

Only use insect netting if necessary for crop production; it can reduce airflow and increase tunnel temperatures. If using netting, use the largest mesh opening possible to exclude the target pest(s) and increase airflow area and ventilation accordingly.

Consider worker safety. If the tunnels are too hot for plants, they are too hot for humans. Shift the hours spent working in tunnels to early mornings and cool evenings to reduce stress on workers.

When retrofitting perimeter insulation take care to angle the excavation away from the ground posts to avoid soil disturbance which could loosen them and reduce uplift resistance.

Grower Experiences

Original Question

There have been loads of listserv exchanges about tunnels in severe weather conditions. I’ve scanned the archives and am drafting a resource that brings much of that experience together in one place.

I’d also like to try to compile current perspectives about what you all have found to be best practices for managing tunnels in extreme weather.

Grower Responses

Excessive Rain / Flooding

· I just walked some of our fields again today. Like last year, they are soaked enough I cannot put a tractor with ag tires on it unless I want all sorts of ruts. That reminded me of travelling in Holland and seeing acres of land under continuous glass houses there. With our continuing spring to early summer rains and fall to earl winter rains perhaps we are going to have to do the same thing with plastic they are doing with glass.

· All of those issues you’ve listed should be addressed before construction. Lots of water comes off a greenhouse in a heavy rain. Where’s it going to go? You can channel gutters into underground PVC and divert the flow to a grassy spot or use a dry well.

· French drain all around the GH! Fill the trench with coarse material so the water goes rapidly to the drain. Make sure the terrain has been sloped so the water does not stay around the greenhouse. This will also prevent cold thawing snow to enter the GH in the spring, really reducing soil temperature on the sides. You really have to be careful during construction so the anchors of the GH are in undisturbed soil (closest to the trench of the drain as possible) or that you reach proctor compaction test required by the manufacturer.

· Actually I started with structure but I’m going to go back to site work to strategically divert water in heavy rainfalls. We’re moving one tunnel that water likes to run into, and I’m thankful that we had a good excavator operator who sited our tunnels well.

· All my tunnels are above grade. I can’t believe anyone would build a tunnel on grade unless adding positive drainage in some form, ditch or tile. The number on question i get from other growers is “how do i keep my tunnel dry?” And my answer is “Do anything, just don’t do nothing!”

· [from MIKE BISOGNO, RIMOL] Site selection is key to prevent damage from rain and flooding. Do your due diligence to ensure your site has good drainage and is not in a flood risk zone. A French drain or swale drain system dug around the outside of your tunnel can help with drainage.

[from MIKE BISOGNO, RIMOL] Polycarbonate baseboards hold up better against water damage. Wooden baseboards will rot over time and can cause rain to backfill into your tunnel if they are not dug deep enough into the ground.

Strong Wind

I put straps over my plastic every other bow. All the farms in Asia have straps over the high tunnels. I’ve been meaning to send pictures and hopefully will get to that soon.

· When we bought our first gutter connect I had it engineered for 80 mph winds and peak to peak snow load. When we get cheaper tunnels, we get trusses every bow and extra wind bracing.

· [Strong Wind and Heavy Snow] Our best strategy for this is buying tunnels from Ledgewood or other places that sell hefty frames with substantial wind kits.

· We did have a tree fall on a tunnel last season. It damaged the plastic and bent the frame but we were able to roll the tree right off the structure and used the wood to make a garden bed alongside the tunnel. This was a home-bent greenhouse from top rail fencing.

· make sure there is no holes in which wind can enter the greenhouse! There are some wind/rain sensor that can close rollups and roofs if there is too much wind. Windbreaks also does a great job of reducing wind speed, make sure they don’t shade the GH. Mine were planted in 2012 and really… It works! Great investment!!!

· For high winds the most important thing is to shut all the doors and keep the wind out!

· … we start with the structure. Has to be burly to withstand wind and snow. We like Ledgewood, Rimol or Harnois. We also like an extra tall tunnel like the taller posts that Ed from Ledgewood offers, which provides both more space for snow to fall off the roof (read, less plowing) and more side ventilation in the heat. We also like a double layer, inflated tunnel because it helps A LOT with shedding snow and increasingly, ice. Two layers also help reduce friction caused by plastic rubbing on poles in the wind.

· Wind, we close the corners up with wiggle wire, and secure all doors.

· We have an Ed Persons [LEDGEWOOD] house. It has survived hurricanes. We close it up tight. We tie the roll up sides tightly together so they do not flap at all during storms.

· Wiggle wire down roll up sides, brace doors cinder blocks/ rebar.

· [from MIKE BISOGNO, RIMOL] Tunnel design is critical for standing up to high winds. Some key design elements to look for include: a truss and truss brace on every bow; wind bracing on all four corners; and a strong purlin-to-bow connection (such as a cross-connector rather than a two-hole pipe strap or through-bolted).

· [from MIKE BISOGNO, RIMOL] We recommend closing up the tunnel during high winds. Wind can damage anything that is not secured. End wall framing and doors can be a weak point. We highly recommend strong end wall framing that is secured in the ground. Failure of an end wall can let wind rush in and act as a scoop, pulling the ground posts out of the ground.

· [from MIKE BISOGNO, RIMOL] If you are at elevation, you may also want to consider a shorter structure. The taller your tunnel, the more wind will be an issue.

[from MIKE BISOGNO, RIMOL] Tunnel maintenance is also important to protect against wind damage. Regularly do a perimeter walk to make sure the rope system for your roll-up sides is taut and your poly is locked in place and does not have any tears.

Heavy Snow

· Snow is not as much of an issue as it used to be but there still is an occasional heavy, wet storm. Don’t buy a greenhouse from down south unless you can dictate the structure’s construction needs. You don’t have to buy one off the shelf.

· Specifically for snow, we snowblow around the tunnels and try to maintain the same paths all winter. During or after a storm, we snowblow the paths, pull the snow off the greenhouses with a cushioned snow rake and re-blow the paths. Haven’t had to do this much in the last two winters.

· Also using the snow removal strategy that Ed [Person, of Ledgewood] always shares about pulling a little bit of the snow off from the middle of one side and then going around and doing the same thing on the other side. It takes forever.

· I have lots to say about snow managing on the GH! Here we have 2 layers of plastic inflated. There is 2 solutions: first: heat so the snow melts as it is falling, second: shovel. Heating costs a lot and I am questioning about the environmental impact. BUT it is the best way to manage freezing rain that will rip your GH plastic as soon as the wind will lift the ice plates. Shovelling is hard on plastic and you need to be carefull!. Make sure there is a certain balance in snow load on each side of the greenhouse so the snow load does not push de GH on one side. In multichapel GH I find electric heating cable in the gutter does a good job in freeing the path so the melting snow can evacuate. You cannot rely only on the heating cable to melt all the snow in the gutter. The snow around the heating cable will melt creating a tunnel so you need to climb up there to break the tunnel so there can be contact between the heating cable and the snow/ice. You also need to climb up there and push the snow with a sleigh shovel all the way to the end (and the beginning) of the gutter. What has made the biggest difference here is to first free the south side so the sun can get into the GH and help to melt the snow on the roof (my multichapel are east-west). When snow has started to melt it creates a fine layer of ice and it is much easier to remove big chunks of snow. That way you can fill your shovel with 2-3 times more snow which reduces by 2-3 times the time you spend pushing the snow to the end of the gutter.

· Buy roof snow shovels with long extensions [and a] good pair of snow shoes!

· [from MIKE BISOGNO, RIMOL] Consider snow drift when choosing your high tunnel site. If you have multiple tunnels, space them out as much as possible (ideally 12’ or more apart if snow removal is needed) so there is room for snow to slide off and build up. Don’t build too close to a barn or other structure that could drop snow or ice onto your tunnel.

· [from MIKE BISOGNO, RIMOL] Tunnels with steeper roof pitch will hold up better against heavy snow; look for a 6/12 roof pitch for optimal snow shed. Even one degree less can make a difference. The gothic shape is designed to shed snow.

· [from MIKE BISOGNO, RIMOL] Do not let snow build up along the sides of your greenhouse – keeping the sides cleared will make sure the snow on the roof has a place to slide.

· [from MIKE BISOGNO, RIMOL] A 36-inch, soft bristle shop broom works well for clearing snow from poly. Use the brush to bounce the poly between bows, which will help snow naturally drift off and minimize the risk of tearing.

[from MIKE BISOGNO, RIMOL] As extreme weather increases, so do engineering standards. Ask your tunnel manufacturer for engineering data around snow/wind loads.

High Heat

· Long-term: planting grapes along the edges of the tunnel. I know this is a weird one that’s impractical for many but we’re excited by what we’ve been doing for the past 3 years in our coldframe. Grapes don’t leaf out until mid-June so they’re not going to cool down the space in spring (when we want it to heat up – except for those 90 degree days we’ve been getting in May). They are easy to trellis/prune and this process generally happens in early spring and fall. Their canopy hangs up at the crossties for us. It took about 2 years for them to get large enough to shade the space. This is still a new thing for us and we’re learning as we go but it looks promising because it doesn’t involve plastic shade cloth, much maintenance during the main growing season and could yield us a saleable crop. We started with concord-like table varieties that are proven in this zone but are starting to plant warmer (and tastier) varieties.

· Other strategies: we’re no longer using plastic ground cloth and that has helped keep the spaces cooler. We mulch with straw in the beds and use wood chips in the pathways.

· Hard to get temperature inside tunnel lower than outside temperature. I would say adjust irrigation to make sure plants do not suffer any water stress during these conditions. The plants will reduce tunnel temperature by evapotranspiration. Opening roof on the greenhouses really does a great job of letting the hot lighter air get out. Never tried shadecloth. I think the key is irrigation and making sure your GH is filled with plants.

· For hot weather we spray Kool ray paint over the greenhouses and tunnels, it really cuts the extreme heat and washes off with the first snows. Environmental safe as well…

· Ventilation and air movement feels essential for all times of year, I don’t know if that is really extremes, but I wouldn’t consider building a tunnel if we couldn’t run power for circulation fans.

· Then there’s shade cloth. We’re slowly building up our supply so that we can toss 30% shade over production tunnels and 50% over our propagation house.

· Then irrigation. Essential always, but it’s been really helpful to install timers in all of our tunnels so that we can increase frequency of watering during heat waves without having to go out and do it manually. Cucumbers especially respond poorly if underwatered during heat.

· [from ED PERSON, LEDGEWOOD] High heat events are difficult to mitigate but there are some things that can help reduce damage. Make sure that roll up sides are rolling completely to the hip board and that they roll up evenly from end to end. It might be a broken screw holding the roll up pipe together, clips that failed from age or poor installation.

· [from ED PERSON, LEDGEWOOD] Make sure that irrigation systems are working properly and boost watering to help the plants take up as much water as possible.

· [from ED PERSON, LEDGEWOOD] Low percentage shade cloth can help reduce heat and light stress. Short term use is all that is needed in most cases. Shade can cause stretching of plants and slowed maturity of some plants.

· I would love to learn more about warm climate growers who are growing lettuces in shade houses and how this practice can be adapted to New England— what % shade cloth should we be using for tunnel lettuces/ greens in June/ July/ august? The disease pressure after these weeks with 3” of rain is just too high…. Love being able to control water in my tunnel but need to invest in shade.

· Every tunnel has overhead irrigation in the frame above. So, we often use overhead to wet things, just 10 minutes, maybe a few times a day. EVEN FULL-GROWN TOMATOES! They do dry again! People needn’t be so paranoid about wet, that they lose flowers and fruit.

· We use shade cloth. 30% on everything. Some years it is on for months, some years it is on for days. This year, it was on for 3 days, and currently is off. I can’t believe people do not just own shade cloth for every tunnel. It is so cheap. Our days are long!! in summer. Your plants can afford the lack of photons.

· [from MIKE BISOGNO, RIMOL] Tunnels with high sidewalls (6’) cool most effectively.

· [from MIKE BISOGNO, RIMOL] A ridge vent can provide additional ventilation and can get you as close to outside air temperatures as possible. An environmental control system and/or automated roll-up sides can also make cooling more efficient and timely. These can be added onto existing tunnels and may be eligible for NRCS funding as part of the On-Farm Energy Initiative program (ask about CPS code 374).

· [from MIKE BISOGNO, RIMOL] Sunlight and heat degrade poly over time. Regularly replace your poly to ensure its UV blocking properties are working optimally.

[from MIKE BISOGNO, RIMOL] If you’re using shade cloth, look for white shade cloth rather than black– it will keep the tunnel cool while still letting in light that your plants need. Using a double wire lock system for roll-up sides facilitates the easy addition of shade cloth.

Other

· Computers are great teamed with weather stations if you can afford them as they work if you’re not there.

· …the best investment I ever made was an automatic generator!

· We have some goals of minimizing plastic and using wood where ever possible – this makes repairs and disposal easier and cheaper. Since damage to tunnels is a given (through wear and tear or extreme weather) using materials that are easy to work with, don’t require special skills or tools and can be composted (like wood, straw,etc) helps us recover from damage.

· It is stupid to say but it is important to inspect the structures every year or once every 2 years (who really take time to do that). Having constructed all my GH myself (including the multichapel) really gave me a profound understanding of how they are made which really help troubleshooting/preventing any problems (so far). BUT I have a personal interest in doing so and the time spent doing this was not spent doing other things that might have been more productive or lucrative (opportunity costs). Having some kind of middle size farm, I can hire a person that is responsible for infrastructure maintenance (or hire somebody to manage the fields crop while I do the maintenance).

· Our main tunnel was bought used many years ago and has given us no problems. It has roll-up sides AND an exhaust fan that runs a lot these days, which I think helps to prevent overheating. We shut it down for the winter so there is no heat. Double poly cover with inflation fan seems to keep snow from collapsing the thing- we have maybe become lackadaisical but we don’t shovel or plow there sides any more just let snow build up and slide off.

· For extremes we think about heat, snow, wind to some extent, and mitigating quick weather or temperature swings (think a cold snap in early spring)

· I’m also thinking a lot about people management in tunnels. We don’t typically get to field work until after harvesting, but I can’t send people out to trellis in those hot temperatures, so having an SOP regarding working in the heat or starting work earlier, which is tough with a remote workforce (that has to commute).

· One thing that feels more frequent with the weather swings is power outages. The winds and snows (especially the wet snows we’ve been having in recent years) are adept at knocking power out, so we’ve had to be sure we have a generator on hand and backup heat for tunnels. Backup heat is also helpful for those springtime cold snaps.

· I’m SUPER CURIOUS about using the heat socks popular in Canada for creating some sort of movable low input heating system to help mitigate those cold snaps. Like an electric garage heater hooked up to a heat sock that you can put in whatever tunnel happens to have your tomato crop. Lower cost than installing a propane heater, and movable to promote crop rotation. You know, in case you’re looking for a project or something. 🙂

We have been building 18’X12′ end of GH leanto’s. They are short of the peak by 4′ so we can build end wall peak vents to get rid of heat buildup… we try to send a photo. all the best .

References and More Information

Bartok, J. (2021, August 24). Engineering High Tunnels for Better Performance. Integrated Pest Management. University of Connecticut. https://ipm.cahnr.uconn.edu/engineering-high-tunnels-for-better-performance/

Callahan, C. (2021, November 5 revised). Tunnel and Greenhouse Ventilation. UVM Extension. Blog Post. http://go.uvm.edu/tunnelventilation.

Callahan, C. (2022, April 19). Calculating Greenhouse and Tunnel Heat Loss. http://go.uvm.edu/greenhouseheatload.

Callahan, C. (2022, April 18). High Tunnel and Greenhouse Heating and Cooling Calculator. UVM Extension. https://go.uvm.edu/tunnelheatload.

Daigneault, A.(2022, January 27). Climate Adaptation for Vegetable Farms. Research Nugget [Video recording]. https://www.youtube.com/watch?v=tuyCxEpqeNw

Gerard, B. High Tunnels and Shade Cloth Buffer Peak of Abundance Farm from Extreme Heat. USDA Northwest Climate Hub. https://www.climatehubs.usda.gov/hubs/northwest/topic/high-tunnels-and-shade-cloth-buffer-peak-abundance-farm-extreme-heat

Guan, W. (2017, June 8). Add Shade to High Tunnels. Vegetable Crops Hotline. https://vegcropshotline.org/article/add-shade-to-high-tunnels/

Hannan, J., Nair, A., & Lang, K. July 2017. Managing a Warm Summer in a High Tunnel. Small Farm Sustainability. Iowa State University. Retrieved August 8, 2024, from https://www.extension.iastate.edu/smallfarms/managing-warm-summer-high-tunnel

Montri, A. (2021, February 24) High Tunnel Storm Protection and Routine Maintenance—Farminar [Video recording]. . Practical Farmers of Iowa (Director). https://www.youtube.com/watch?v=OEmIrxnwo4A

Odneal, M. (2017, November 9). Water Drainage at High Tunnel Improved. What’s Happening in the Field? Missouri State University. https://blogs.missouristate.edu/fruitexperimentstation/2017/11/09/water-drainage-at-high-tunnel-improved/

Rimol Greenhouses. (2024, August 21). Will Your High Tunnel Hold Up to Extreme Weather? The engineering details matter when it comes to high tunnel strength and durability. Blog Post. https://rimol.com/posts/will-your-high-tunnel-hold-up-to-extreme-weather/