Many farms are exploring market diversification and season extension by drying or “curing” herbs and flowers. Whether the crop is culinary herbs (e.g. sage, rosemary, thyme), traditional herbal medicines, decorative flowers, hops for brewing, or CBD hemp the basic approach is the same. Drying boils down to removing water from plant matter by evaporating it into the air. Curing is generally a slower process that ensures a more gentle drying process which is well distributed throughout the part being dried.

Over time, drying reduces the weight of the crop as more water leaves the plant matter. The removal of water serves as a way to preserve the plant matter by removing moisture that would otherwise support bacterial and other decay mechanisms.

Drying and Curing: The Basics

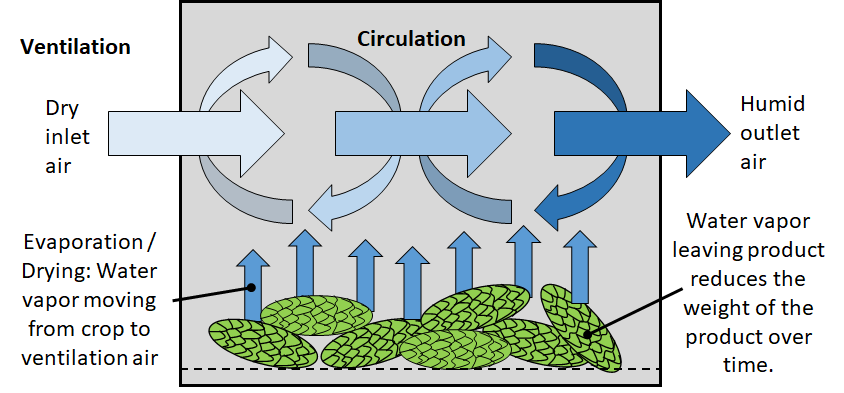

- Passing relatively dry air over freshly harvested crops drives moisture from the crop into the air.

- The dry inlet air becomes more humid as it passes through the crop (circulation) and exits with more moisture than it started with. This humidified air is removed from the drying space and replaced with fresh, dry air (ventilation).

- Over time, this reduces the weight of the crop (by removing water) and leads to lower moisture content (MC).

- By reducing the moisture content (MC), the water activity (aw) of the crop is reduced which inhibits growth of microorganisms such as mold.

This relatively rapid removal of water prevents decay and reduces the water content that would normally promote mold and fungal growth. The process of drying reduces the “moisture content” of plant products typically from 80% to approximately 10%. Moisture content is the percentage of the plant’s weight that is water. The net result is a reduction of “water activity” which is a measure of how much water is actually available in the product. As water activity is reduced, spoilage organisms and pathogens have a more difficult time surviving which results in a longer storage and shelf life. The video below demonstrates how to measure moisture content and a moisture content calculator is available to help with this.

Since plant matter is typically 80% moisture content at harvest and we typically want to dry it to 10% for storage, that means we have to remove water. A lot of water. How much water? Take, for example 50 lbs of hops that are at 80% moisture content. The water content of these hops is 50 lbs x 0.80 = 40 lbs. To dry them to 10% moisture content we need to remove 39 lbs of water (4.7 gallons).

Working at a larger scale? For every ton of harvested crop you’re looking at removing 168 gallons (1,390 lbs) of water through evaporation.

Drying vs. Curing

Drying and curing differ mainly relative to temperature and humidity used in the process. They also are used for different crops and for different intended markets.

| Drying | Curing | |

| Motivation | To minimize drying time, higher temperature air is preferred | To maximize desirable oils, lower temperature air is preferred. |

| Temperature | 90 F or above | 90 F or below |

| Humidity | 50% RH or below | 50% RH or above |

| Crops | Culinary herbs, extract and biomass CBD hemp | Aroma hops, smokeable CBD hemp, anything where aroma and visual appearance is critical. |

Common Drying Methods

Ambient Air

Window screens, Hanging in barns, Benches in unheated high tunnel, etc.

Drying can be done very simply with essentially no cost. A window screen on saw horses in a shaded space can serve as a very effective drying system for small volumes of product. The screen provides a ventilated surface for the plant matter to be spread out in a thin layer. This maximizes the surface area of the plant matter exposed to the air surrounding it.

Plants can also be bunched together with twine and hung in a dry place to dry.

When drying in ambient air, be sure to allow plenty of open air space around the drying area. The plants being dried should be as open to the air as possible. This means minimizing the amount of product that is in contact with solid surfaces such as tables or framing and also spreading the material out into, ideally, a single layer.

A well-ventilated space is helpful in this process so open windows and doors if needed. A simple box fan can be used to circulate, or mix, the air. More powerful fans or blowers such as those used for ventilating greenhouses can also be helpful.

Heated Air

Greenhouses, Heated high tunnels, Electric heaters, Fans, Oasts, Drying barns, Plenums driers, etc.

As noted above, heating air increases its ability to carry water as evaporated vapor. The higher the temperature of the air, the more water vapor it can carry. Higher temperatures also increase the rate of diffusion which increases how fast water vapor can diffuse into the air to be carried away.

Let’s consider, for example, a high tunnel with a relatively modest, single 36 inch diameter exhaust fan with a ½ HP motor on one endwall and inlet louvers on the other end. This fan is rated for about 10,000 cubic feet per minute (CFM) of air flow. On a typical September day in Montpelier, VT we might expect the temperature to be 55 F and the relative humidity to be 60%. This outside air has some moisture in it (60% of the maximum it can carry before it rains). The 10,000 CFM airflow provided by the fan in combination with the moisture carrying capacity of the ambient air means it can carry about 250 pounds (lbs) of water per hour. That is moisture that it can remove from the crop if the space is well mixed and evaporation is allowed to happen.

If the outside air is heated from 55 F, 60% RH to 80 F, it can carry 700 pounds of water per hour. So, you can dry your crop almost three times faster by heating the air 20 F.

Sun Drying

Tarps in the Sun, Greenhouses, etc.

Drying fruits and vegetables by laying them out in the sun has a long history and is common in many parts of the world. This practice is not common when drying herbs and flowers because they lose color, flavor and volatile compounds that are often the reason for the harvest.

As noted above, high tunnels and greenhouses do offer a large, open space that is very attractive for drying high volumes of crops. They often have wire benches and ventilation fans that help in the process. To avoid excessive exposure to sunlight growers generally install 50% shade cloth or paint the exterior with a temporary shading coating such as kaolin clay or KoolRay™.

Dehumidifiers

Some growers have opted for using dehumidifiers to lower the RH of the drying air. These units use electricity to run a refrigeration process that dries the air by condensing water on a refrigeration coil. The air is then re-heated before being sent back out of the machine. This results in relatively dry air at roughly the same temperature it was when it went into the dehumidifier. Growers who have used these have chosen them because they work at low temperatures and because are packaged units that can be easily installed, replaced, and moved. They also are fueled by electricity which is an attractive option for some compared to fossil fuels.

Dehumidifiers are generally rated in terms of the volume of water that they can remove (condense) from air per day. This value is typically in the range of 30-70 pints per day for a household type dehumidifier. Multiple units can be used together. Water weighs 8.3 lbs per gallon and there are 8 pints in a gallon, so each pint weighs a little over 1 lb. These household dehumidifiers can, therefore, remove about 30-70 lbs of water from the product per day. Take the case of a 70 pint per day dehumidifier. This unit can condense 70 pints of water from the air or 73 lbs. If your crop is starting at 80% moisture content and you hope to dry it to 10% moisture content, you need to remove 70% of the moisture content in the starting weight. With this dehumidifier you can, therefore, expect to dry 104 lbs (starting weight) of crop in a day.

Remember, that even with dehumidifiers, air circulation is very important. The air needs to be mixed and flowing over the product in order to dry it effectively.

Dehydrators & Ovens

Dehydrators are tiny, packaged drying rooms. They often have multiple trays and can provide very good control of the drying conditions. They typically have heaters, circulation fans and ventilation fans built in. A kitchen oven on the “warm” setting or run at a low temperature and then shut off before loading product can also provide a drying space. These can be a very good way to dry small batches of trial varieties and also helpful in determining the moisture content of plant matter to inform harvest timing and drying completion.

Determining Moisture Content of Herbs

The moisture content (MC or %MC) is a measure of the amount of moisture in something compared to the total mass. There are technically two “bases” for moisture content; “wet” and “dry.” Wet basis is the most commonly used and is the amount of moisture (water) divided by the amount of total mass (wet and dry).

One easy and low cost way to determine moisture content is to use the “microwave” method.

The Microwave Method

- Take a sample. If using a container or bag to contain the sample, be sure to know its mass or “tare” the scale with it.

- Weigh the sample and note that weight (“wet weight”)

- Dry it completely. You can do this carefully in microwave (5-10 seconds at a time) or any other means such as low oven or dehydrator. You know you’re done when there is no change in mass between drying phases.

- Note the final weight (“dry weight”).

- The amount of weight (mass) lost (wet weight – dry weight) is the moisture mass of the sample.

- Moisture content is typically provided on a “wet” basis which means you must divide the moisture mass by the total starting mass (wet weight). That is a decimal fraction representing moisture content. E.g. 0.14 = 14% moisture content. The calculators below do the math for you.

Drying Calculator: http://go.uvm.edu/herbcalcweb (this includes step by step instructions for the “microwave” method.

Downloadable (Excel) version of calculator: http://go.uvm.edu/herbcalcxls

You can do the same thing for target moisture content and/or to know what your moisture content is during drying. Some growers do a clever thing like use a 100 gram sample as their starting sample. This makes the math easy in the end since your result is just divided by 100. You can also make 100 gram sample bags (tare the bag weight) and have them in with your drying batch. This lets you monitor the mass of the sample as the whole batch is drying.

The video below provides more information on how to use this method.

Much of the information above was compiled jointly by Chris Callahan (UVM Extension) and Gretchen Schimelpfenig (Resource Innovation Institute) as part of a Hemp Drying Basics session for the 2020 Summer Hemp Webinar Series and for the 2021 UVM Industrial Hemp Conference.

Share this resource

Share this resource easily using the following shortlink: http://go.uvm.edu/herbdrying.

References and Resources

- How Do I Dry Herbs? National Center for Home Food Preservation. https://nchfp.uga.edu/how/dry/herbs.html.

- The Potential of Herbs as a Cash Crop: How to Make a Living in the Country. Miller, R. A. 10 Speed Press. https://www.goodreads.com/book/show/635348.The_Potential_of_Herbs_As_a_Cash_Crop

- Hops Moisture Calculator (Can be used for any crop being dried or cured). UVM Extension Ag Engineering. Web Version: http://go.uvm.edu/herbcalcweb. Excel Version: http://go.uvm.edu/herbcalcxls.

- HVAC for Cannabis Cultivation & Controlled Environment Agriculture. G. Schimelpfenig. Resource Innovation Institute. http://resourceinnovation.org/Resources/

- Improved Sun-drying and Solar Drying: Basic Considerations and Selected Applications. United Nations Food and Agriculture Organization. http://www.fao.org/3/x5018e/x5018E0h.htm