To learn more about forced air cooling visit go.uvm.edu/forcedaircooling

To download the PDF version of this plan click here!

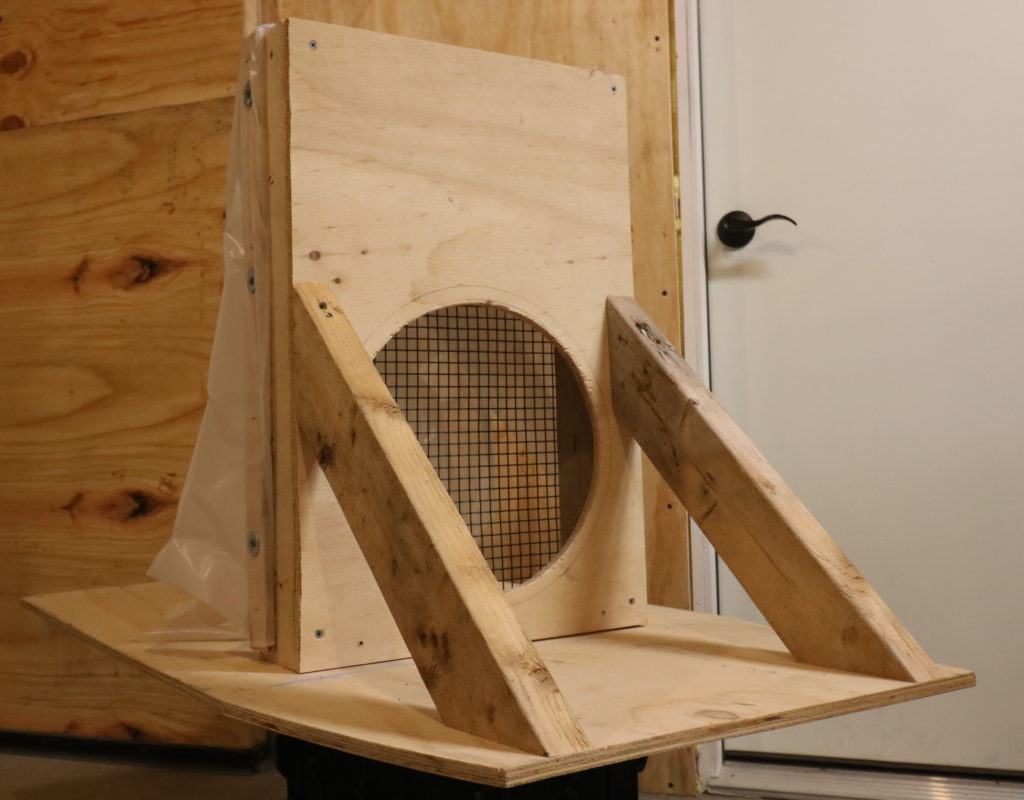

Farms that need to cool smaller volumes of produce can also benefit from forced air cooling. Whether cooling stacked pallets, pallet bins or individual cartons, the same principals apply. A smaller pallet cooler was noted on the previous page, but this concept can be scaled down even further to fit your needs. Here is a prototype, that could fit on a countertop with-in a walk-in cooler.

Framing:

Constructed of 2×4’s on top of a horizontal base made from 1/2” plywood cut 24” deep and 44” wide. Angled reinforcements were needed to stiffen the assembly.

Plenum Panel:

The plenum (vertical wall) was built 16” deep by 24” tall and assembled with decking screws. 1/2” Plastic coated hardware cloth was used to provide a back-stop for the carton being cooled, to keep the plenum space from being closed, and to provide proper air flow from the end of the crates through the product and out through the blower.

The plenum (vertical wall) was built 16” deep by 24” tall and assembled with decking screws. 1/2” Plastic coated hardware cloth was used to provide a back-stop for the carton being cooled, to keep the plenum space from being closed, and to provide proper air flow from the end of the crates through the product and out through the blower.

Plastic Wrap:

4-mil poly is fastened to the top and two sides of the plenum, and long enough to extend over your desired number of bulb crates or vented boxes you wish to cool at once. This was secured with decking screws through fender washers with the plastic wrapped around strips of plywood.

Blower:

The blower used was the same 12” blower from Global International as the pallet cooler. A 11 1/4” hole was cut out of the plenum to provide the suction air inlet to the blower.

Bill of Materials—Carton Cooler

Framing Lumber, 2”x 4”x 8’ (1) …………………………………. $5

Plywood, 4’ x 8’ x 1/2” (1) ………………………………………. $25

Decking Screws, 3” (1 box) ……………………………………… $10

Decking Screws, 1-1/4” (1 box) ………………………………. $10

Fender Washers, 3/16 x 1-1/4 (1 box) ……………………… $10

Plastic, 4 mil, 20’x25’ (need 64”’x36’) ………………………. $13

Blower, 12” Portable Ventilator Blower …………………. $125

Total Cost ……………………………………………………… $198