Welcome to another hop season! We are gearing up for the growing season and first on the to-do list is spring crowning.

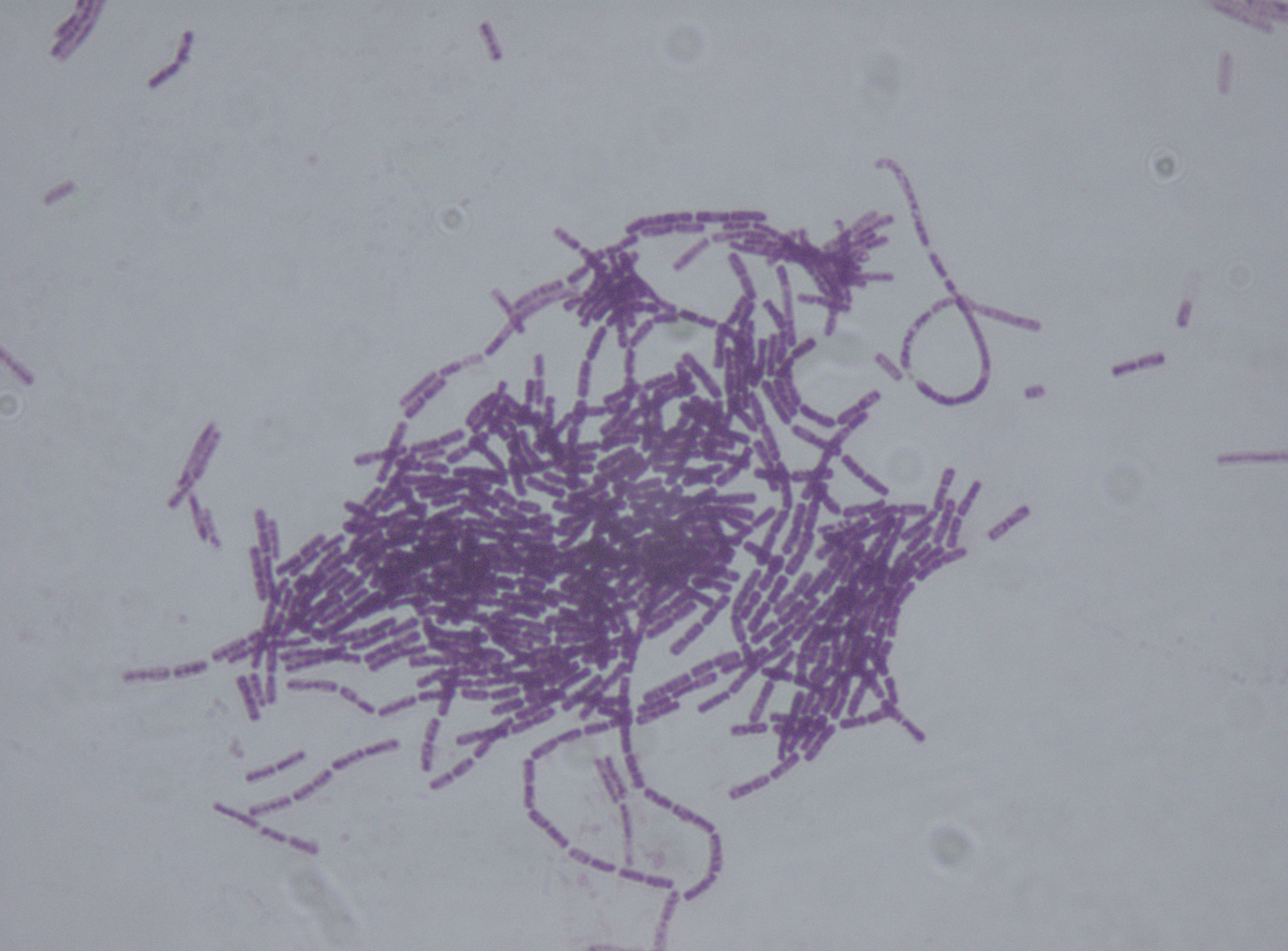

As you know, Downy Mildew (DM) is a major concern for us in the Northeast and we must use every tool we have to manage it. DM can overwinter in the plant crown and will emerge with the first shoots–if left unchecked, it can spread and try to increase its foothold in your yard.

“Crowning” is the practice of removing new growth as well as the very top of the hop crown early in the season. Removing new growth without going as deep as the crown is often referred to as “scratching” or “pruning.” Crowning is typically accomplished through mechanical means, but removing shoots by other means such as chemical burndown or flaming is also known to be effective, but does not affect inoculum living in the crown.

Crowning reduces the amount of plant material that is above ground and available for DM spores to land on during wet spring conditions that are ideal for infection. Cutting the plant back is an advantage for managing disease; however, it also reduces the time the plant has to grow to the top of the trellis, which may likely reduce yield. This is why the timing of crowning is so critical – we want to crown early enough that the plant has ample time to grow back.

Our team has been conducting trials on timing at our hopyard at Borderview Research Farm in Alburgh, Vermont. So far, our trial results suggest that crowning in mid to late April has yielded the best results. For example, in 2015, our early crowning date (23-April) yielded better than the late crowning date (13-May) AND performed better than control plots that were not crowned at all. The later date in May had a larger reduction in disease, but suffered in yield. So, it seems like early crowning is the sweet spot between good yield and disease management. See the full results of our crowning trial here: 2015 Hop Crowning Trial.

We think that crowning early may have the added benefit of allowing the soil to warm quicker by removing excess material covering the soil and generally turning/aerating the soil a bit. We mulch our hop yard, and the mulch can act as an insulating layer, keeping the hops cooler than the air temperature in spring. The high yields from our early-crowned hops may be partly due to warmer soil temperatures.

Crowning Equipment Options

Want to know what equipment to use? There are several options!

For small acreages, if you are on a budget and/or would like to test crowning in a small section of your yard this year, it might make sense to use something similar to a walk-behind trimmer. We currently use this unit for crowning. It has been modified with a metal blade with teeth to better cut plant growth. One challenge to using this piece of equipment, other than time, is consistency. Where other implements cover the whole bed at a constant height, this trimmer is used to target the specific plants as their shoots appear from the ground, and relies on the operator to maintain consistent depth.

Our team is currently shopping for a tractor-mounted crowner. The unit has sharp discs that prune back growth while the rotation of the discs spreads soil and mulch above the blades. This tool may be a good fit for those who hill their hops and need to cut the bed height down at the beginning of the season.

Other implements have tines that cultivate the soil surface and remove growth (like the John I. Haas crowner pictured on right). What ever equipment and technique you choose to use, crowning is an important practice for disease management, and also has a large effect on the growth timing of your plants. Remember that you want those plants at the top of your trellis by the beginning of July, so your crowning and training should be built around achieving that.

Stay tuned for future posts on training. Until then, keep calm and hop on!