![]() A downloadable/printable pdf of this article is available here.

A downloadable/printable pdf of this article is available here.

Introduction

The preservation of quality in fresh market and storage crops on small and medium-sized farms in the Northeast depends on the rapid reduction of pulp temperature and maintenance of relatively low temperatures to slow metabolic respiration.

There is strong foundational work showing that rapidly reducing the temperature at the start of the cold chain increases product quality when delivered to the consumer. Postharvest handling is critical for fresh produce farmers and the markets they sell to. Effort and expense invested in growing fruits and vegetables can be wasted without good handling practices at and following harvest (Gross 2014). Consumers expect the best from fresh produce. Quality and freshness are ranked with high importance among consumers. Farmers market respondents respectively rank quality (63% ) and freshness (59%), as highly important factors in their buying decisions. Nearly 87% of the respondents indicated that availability and quality of fresh produce affected their decision about where to purchase (Gorindasamy 2002).

Precooling involves flowing a controlled, chilled fluid (air or water) over the product to improve heat transfer for removal of field heat to depress respiration and initiate the cold chain.

Precooling

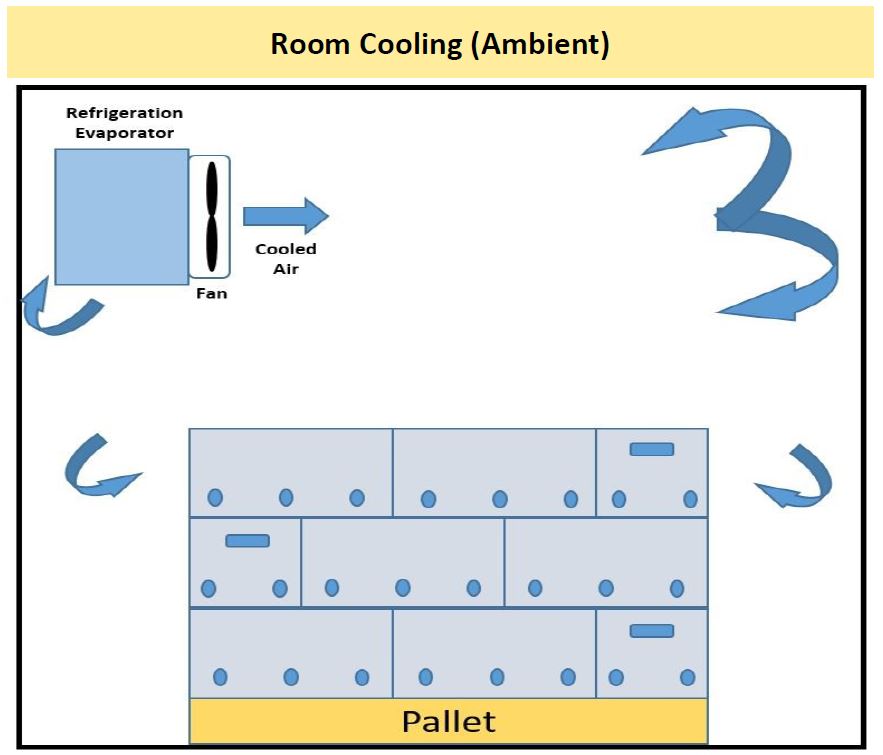

One of the most important postharvest factors influencing quality is temperature. Temperature directly impacts the rate of metabolic respiration and associated decay. Produce which is not cooled quickly degrades in quality (Sargeant 1991). Table grapes, for example, deteriorate more in 1 hour at 90 °F then in one day at 39 °F or one week at 32 °F (Thomson et al 2008). Lower quality leads to a decrease in sales, inefficient use of storage space, and wasted labor due to the time taken to grow, clean, and store product that doesn’t sell. Coolers are a good addition to most farms but fall short of meeting optimal precooling needs. When produce is packed in boxes, stacked on a pallet and directly placed into a cooler, cooling time will be a minimum of 24 hours and may take many days. (Thompson et al 2008).

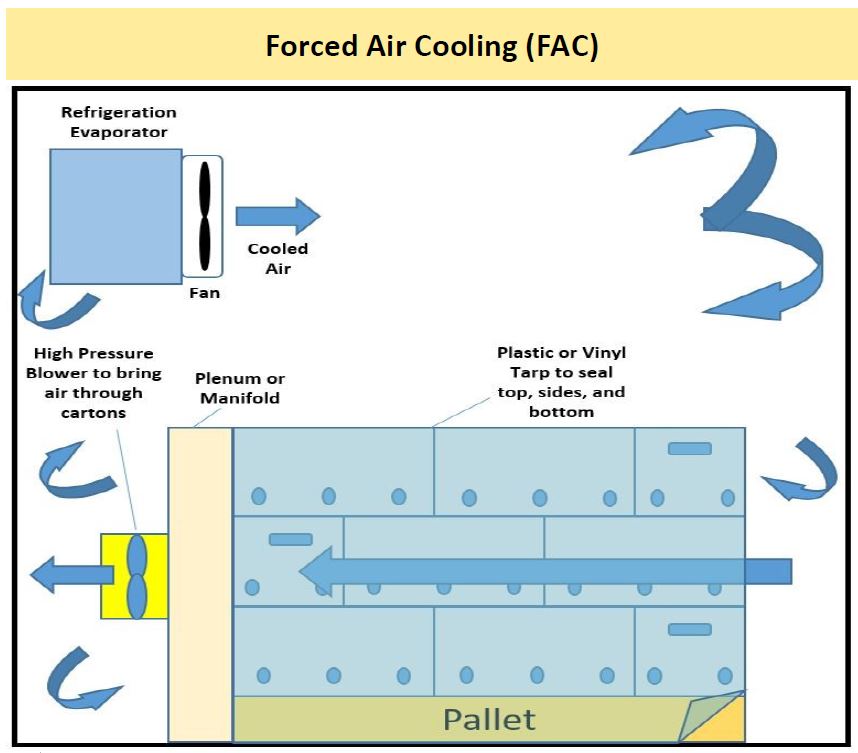

One method to reduce cooling time is through forced air cooling (FAC). In FAC systems, refrigeration cools a space and blowers are set in position to actively draw the cold air through the produce. The cooling time drops from 24 hours to 10 hours or less when using a static cold room due to the increased air flow (increased convective heat transfer) (Thompson et al 2008, Boyette 1989).

Attempts have been made at smaller scale pre-coolers to reduce field heat at harvest in absence of coolers (Thompson and Spinoglio 1996). Retrofitting a cargo container with insulation and cooling with a large capacity air conditioner was also explored (Boyette & Rohrbach 1990). This forced-air cold room offered space for many pallets of produce but it still took many hours to reduce the temperature internally, especially for the boxes on pallets in the center of the container. The key is integrating both cooling and air flow effectively (see Figures 1 & 2).

A mobile forced air cold box mounted on a trailer was constructed and demonstrated in Florida (Talbot and Fletcher 1993) aimed at farms growing produce on 5-50 acres. This unit could be self-built. Experiments showed that grapes could be cooled by 15 °F per hour. For denser produce like melons and tomatoes, the cooling times were longer. The construction cost at that time was close to $5,000.

We have built prototype FAC’s for a single, fully or partially loaded pallet (figure 2) and also a 1-3 carton (either bulb crate or 1 1/9th bushel box) “counter-top” model. The construction details of these units are provided on the following pages of the PDF linked above.

Key Points of Precooling

- Starts the cold chain by rapidly reducing respiration.

- Reduced respiration leads to higher quality over a longer storage and distribution time.

- Cooling is improved with the combination of active cooling and forced air flow with a blower.

- 1-3 CFM of airflow at 0.5 IWC static pressure per pound of product is the rule of thumb for sizing.

- Ventilated containers (e.g. holes or slats) are necessary to ensure airflow is actually through the product.

- Close up any large openings to prevent short-circuiting air flow.

Build Plans

Sound like a good idea to you? Build plans are available for both of these prototypes!

For the pallet-sized unit check out this post –> http://go.uvm.edu/palletcooler

This is a video from a field trial of a modified pallet sized cooler! https://youtu.be/Ccy5KxrVhPk

For the counter-top forced air cooler, take a look here –> http://go.uvm.edu/countertopfac

Field Trials

We performed a series of precooling trials using small-scale forced air coolers to cool eggplant, watermelon, strawberries, blueberries, zucchini, and roasting peppers. The forced air cooling was done in parallel with standard room cooling and was shown to result in cooling rates ranging from 1.2 to 2.2 times faster than room cooling. This test demonstrated the feasibility and benefit of simple forced air cooling systems to smaller scale farms.

You can find the full report here: go.uvm.edu/factrial

Acknowledgments

Funding for this publication was made possible, in part, by the USDA NE SARE program under grant #LNE16-347.