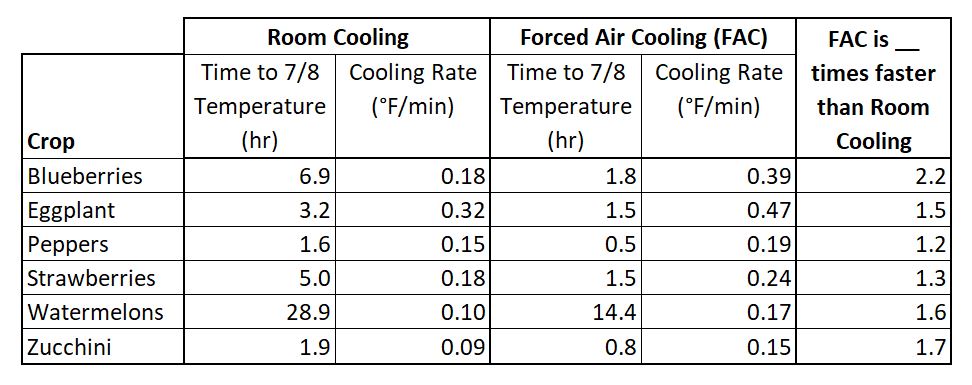

Last summer we performed a series of precooling trials using small-scale forced air coolers to cool eggplant, watermelon, strawberries, blueberries, zucchini, and roasting peppers. The forced air cooling was done in parallel with standard room cooling and was shown to result in cooling rates ranging from 1.2 to 2.2 times faster than room cooling. This test demonstrated the feasibility and benefit of simple forced air cooling systems to smaller scale farms.

Last summer we performed a series of precooling trials using small-scale forced air coolers to cool eggplant, watermelon, strawberries, blueberries, zucchini, and roasting peppers. The forced air cooling was done in parallel with standard room cooling and was shown to result in cooling rates ranging from 1.2 to 2.2 times faster than room cooling. This test demonstrated the feasibility and benefit of simple forced air cooling systems to smaller scale farms.

Background

The rapid reduction of produce pulp and core temperature is important to maintaining postharvest product quality. Forced air cooling is one method that accomplishes this and it is practiced widely among larger scale producers and aggregators. This project was intended to demonstrate this practice and its potential benefit to small and medium scale growers. More information about the benefits of forced air cooling and precooling can be found in the earlier fact sheet available at go.uvm.edu/forcedaircooling

Methods

For these trials, we use small-scale precooling systems intended for farm construction. These precooling systems used simple lumber frames, plywood plenums, axial blowers and polyethylene film plastic to direct cold room air directly over produce to remove field heat. More detail about these forced air cooling systems can be found in the fact sheets and build plan documents available at the following links:

Floor Pallet Model: go.uvm.edu/palletcooler

Counter Top Model: go.uvm.edu/countertopfac

As a result of the willingness of partner farms to collaborate in these trials, the following crops were tested: eggplant, watermelon, strawberries, blueberries, zucchini, and roasting peppers.

In each trial, two batches of the crop with roughly equivalent mass were harvested into standard cartons or bins based on the practice of the farm. One batch was cooled using room cooling—allowing the product to cool as it would when simply set in the walk-in cooler or CoolBot room. The other batch was cooled using a forced air cooling system built from one of the two plans referenced above. The batches were cooled in parallel with a target of reaching 7/8 of the optimal storage temperature for each crop (“7/8 temperature”).

Product temperature was monitored in each batch using an insertion probe thermocouple and a data acquisition system with a 3 second sampling period. These data were used to fit a cooling rate curve using an exponential decay model and minimizing the error between the model and the actual data. The cooling rate curves were used to estimate 7/8 cooling time for larger, more dense crops or those that did not reach 7/8 temperature during the time allowed for the test.

Results

The results of each field trial are provided in individual PDF files linked below.

Forced Air Cooling Field Trial Results

Summary of Results

The table below summarizes the observed cooling rate of each crop comparing room cooling to forced air cooling.

Conclusion

Forced air cooling was demonstrated using two simple systems designed to be built on farm with readily available materials. The method was applied to six crops and demonstrated a cooling rate 1.2 to 2.2 times faster than room cooling achieved. The use of forced air cooling, directing cool room air over packed product, is a common practice in larger production systems and this trial illustrates its feasibility for smaller scale farms.

Acknowledgments

Funding for this publication was made possible, in part, by the USDA NE SARE program under grant #LNE16-347.